When selecting a manufacturing partner for electronic assemblies, the location of your supplier isn’t just a line item in your logistics spreadsheet—it can determine the long-term reliability and success of your product. At Thomas Instrumentation in Cape May Court House, NJ, our focus is on more than just speed and affordability. We prioritize the complete product lifecycle, from collaborative design input to refurbishment and repair, and ensure that our customers are supported by an engineering-first team that never overpromises or underdelivers.

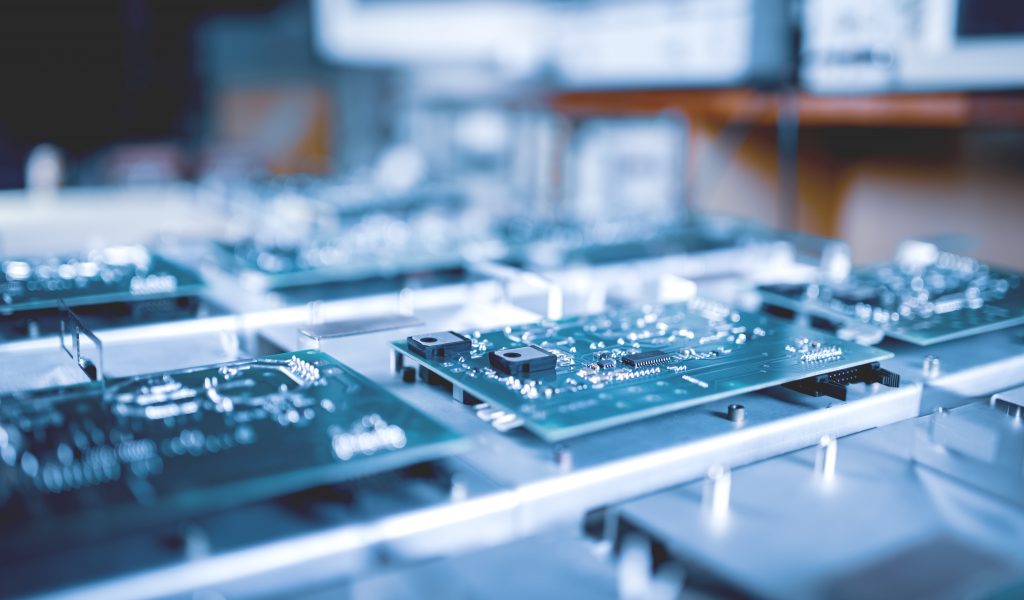

We offer medium-volume PCB manufacturing, embedded software engineering, and electronics design services to a wide range of industries, with a primary focus on industrial controls—our leading area of expertise—as well as industrial IoT, lab instrumentation, smart appliances, telecommunications, and renewable energy. Choosing a domestic manufacturer like Thomas Instrumentation isn’t just a matter of geography—it’s a commitment to reliability, transparency, and sustained support.

Comprehensive Support Through the Entire Product Lifecycle

Unlike many offshore contract manufacturers that prioritize volume over quality, our U.S.-based operation is structured to support your product from concept to sustainment. Whether you’re launching a new design or refreshing a mature product line, we walk beside your team through:

- Design collaboration and early manufacturability analysis

- BOM vetting to prevent future parts obsolescence (EOL risks)

- Low-failure-rate production using IPC-A-610 and ISO 9001:2015 standards

- Lifecycle support, including troubleshooting, repairs, and refurbishment

The value of partnering with a team located in your time zone—who understands your industry and who can provide direct engineer-to-engineer interaction—cannot be overstated. We don’t just ship boards; we engineer solutions with long-term performance and serviceability in mind. Our failure rates approach zero because we evaluate every quote and project with deep scrutiny before production begins.

Our Quoting Process: Intentional, Not Rushed

While fast production can be advantageous, Thomas Instrumentation does not turn quotes overnight—and there’s a good reason for that. Many overseas vendors offer lightning-fast quotes, but often miss critical manufacturing challenges such as sourcing EOL parts, poor component stack-ups, or thermal issues that lead to costly redesigns or failures down the line.

Our quoting process is deliberate. We take time to:

- Evaluate the design for manufacturing (DFM) and testability (DFT)

- Confirm component availability and ensure no future risk of obsolescence

- Validate supply chain resilience to reduce future disruptions

- Confirm that we can support the product throughout its lifecycle

This thorough upfront diligence reduces surprises later, protects your bottom line, and ensures that your electronics can be manufactured consistently at high quality over time.

Lifecycle Support That Builds Trust

We understand that electronics manufacturing isn’t a one-and-done transaction. Products evolve. Firmware is updated. Customers need replacements or service. Unlike many manufacturers who disengage post-production, we remain a true partner through the full lifecycle of your product.

Thomas Instrumentation offers:

- Responsive U.S.-based customer support

- Onshore refurbishment and repair capabilities

- Re-manufacturing services for legacy products

- Engineering feedback loops for product improvements

Our Cape May Court House facility is structured to deliver technical continuity. From initial prototypes to end-of-life service, we support your product and your team—ensuring uptime, field reliability, and customer satisfaction.

Stable Supply Chains and No Tariff Surprises

The unpredictable nature of international shipping, fluctuating tariffs, and political instability can lead to unanticipated costs and missed deadlines when working with overseas suppliers. With a USA-based manufacturer, you get:

- Predictable lead times not subject to customs or port congestion

- Transparent shipping and logistics costs

- Protection against geopolitical disruptions and embargoes

Mid-volume manufacturers (500–1000 units/month) can especially benefit from this predictability. A steady domestic supply chain avoids hidden costs and reduces the risk of last-minute design changes due to unavailable components.

Engineering Excellence and Quality Assurance

Electronics built in the U.S. adhere to stringent quality standards that reduce returns, prevent field failures, and ensure compliance with regulatory demands. Thomas Instrumentation maintains certifications such as IPC-A-610 and ISO 9001:2015, and we apply those standards rigorously across all builds.

Industries we serve demand nothing less than reliability:

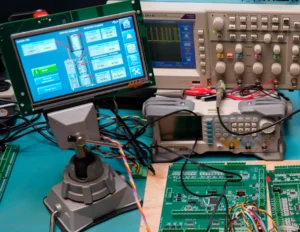

- Industrial controls, IoT & automation: Complex controllers and data acquisition boards built for rugged use

- Telecommunications & smart infrastructure: High-density assemblies powering next-generation networks

- Smart appliances: Embedded systems with strict reliability and UI requirements

- Laboratory & scientific instrumentation: Precision electronics with ultra-low noise tolerances

In addition, we proactively review your designs for issues others often miss. We don’t wait for problems to arise—we catch them before production, saving you time and budget. For more insight into our design capabilities, explore our electronics PCB design services.

A Fit for Medium-Volume Product Strategies

Large overseas manufacturers often neglect medium-volume clients in favor of high-volume customers. At Thomas Instrumentation, we specialize in the mid-scale production market, delivering tailored support to companies who are scaling or iterating product lines.

Our services are ideal for:

- Startups transitioning from prototypes to production

- OEMs updating legacy products with smart features

- Industrial suppliers who need dependable U.S.-made control boards

- Energy & utility companies rolling out connected infrastructure

We provide flexibility, reliability, and engineering insight that large-scale providers simply can’t match at these volumes.

Is U.S.-Based Electronics Manufacturing More Expensive?

At first glance, yes—per-unit costs may be higher. But when you account for the reduced risk of costly delays, the avoidance of tariffs, lower shipping expenses, and the long-term reliability of a well-engineered board, the total cost of ownership is often significantly lower. In fact, companies that cut corners on quality frequently face much higher downstream costs—from product failures and legal liability to reputational damage and lost customer trust. A few dollars saved upfront can easily turn into millions in repair costs, insurance claims, or brand erosion.

Moreover, our engineering evaluation ensures your board can be built consistently for years to come—without costly redesigns or supplier changeovers. That’s the kind of investment that pays dividends.

What Sets Thomas Instrumentation Apart?

With over 40 years of experience, Thomas Instrumentation is more than a vendor—we’re a strategic extension of your engineering team. Our embedded software development, PCB design, and full lifecycle manufacturing support ensure your product performs in the field and stays supportable long-term.

- We don’t rush quotes to win your business—we quote to manufacture your product right.

- We don’t overpromise—we analyze and verify every design before we commit.

- We’re based in New Jersey and staffed by engineers who care about your success.

If you’re looking for a partner who prioritizes quality, support, and lifecycle sustainability over speed-for-speed’s-sake, we invite you to contact Thomas Instrumentation today. Let’s build something reliable—together.