Industrial

Thomas Instrumentation has over 30 years of experience in industrial electronic design and manufacturing. We understand the operational demands of this market and have proven design solutions for them. Some of the key elements we keep in mind during our design phase include:

Harsh Operational Environments

This can include any combination of the following items: unstable power sources, external electromagnetic interference, unsterile conditions (dust, dirt, etc.), hot and humid temperatures, and more.

Ease of Use

Most factory workers are very busy, so we want our devices to be easy to use. Any alerts or messages should be straight forward and clear. Operational settings should be easy to find and enter. Errors should be clear, and diagnostics must be easy to run. We don’t want end users wasting their time trying to use our system.

Device Lifespan

Many of our systems need to remain in active operation for at least 8 hours a day, every day, for a minimum of 7 years. This pushes us to develop reliable designs with parts that have a lifespan over 10 years. We still have some products manufactured in the 1980s in operation.

Some of our industrial control products include:

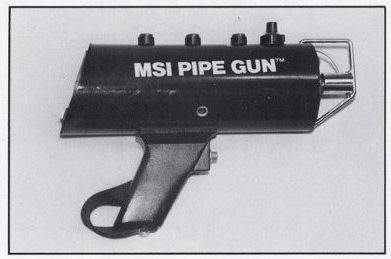

Pipe Gun

This handheld tool allows workers to quickly, accurately, and safely measure how much pipe they have in their inventory. It was originally designed as a tool for pipe yards, drilling rigs, and fabrication shops and is thus designed for harsh conditions. The gun works by sending a series of signal pulses down a tube and timing how long it takes to get a reflected signal. This time measurement allows the gun to calculate and display the length of this pipe.

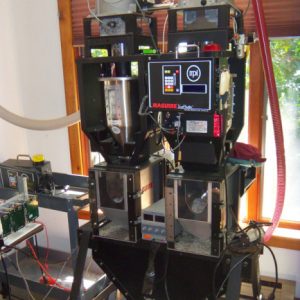

Plastics Systems

[ Gravimetric Blenders; Low Pressure Dryers; Extrusion Control;

Gravimetric & Volumetric Feeders; Loaders; Color Pumps ]

These systems are produced for a single customer who is a global technology leader in material management systems for plastic blending, molding, extrusion, color pumps, and compounding. We have been designing, programming, and manufacturing this customer’s embedded control systems since 1981. The collaboration between our two companies has distinguished our customer’s products from their competitors in terms of accuracy, ease of use, and low cost. These are very reliable controllers built to survive harsh factory conditions. Many of these products have been running 24/7 for over 10 years with minimal amounts of repairs. The basic functionalities included in these controllers are:

- control of pneumatic systems often through solenoid valves

- control of AC, DC, brushless DC, and stepper motors

- control of vacuum pumps or venturi systems

- control of blowers

- control of heaters

- measurement of weight with load cells

- measurement of pressure/vacuum

- measurement of temperature with RTDs, thermocouples, and solid state sensors