Scaling a product line is one of the biggest challenges for manufacturers. Too often, OEMs are forced into a difficult choice: produce small prototype batches at high costs, or commit to massive overseas runs that tie up cash flow and create risks. For many U.S.-based OEMs, an often-overlooked solution lies in medium-volume PCB assembly—typically in the range of 500 to 5,000 units per month. This production tier offers a strategic balance between cost efficiency, quality, and lead time that high-volume overseas factories and low-volume prototyping shops often can’t match.

At this level, businesses can achieve cost efficiency, secure reliable supply chains, and maintain the agility needed to respond to shifting market demand. With a trusted USA-based electronics supplier, OEMs can bridge the gap between prototypes and full-scale mass production without the common headaches of overseas sourcing.

Why 500–5000 Units Is the Sweet Spot

When manufacturers are mapping out production, they often assume they must either produce a handful of prototypes or commit to tens of thousands of units overseas. In reality, most appliance and IoT companies benefit more from operating in the middle ground. Producing between 500 and 5000 units monthly offers enough volume to lower per-unit costs, but not so much that companies are overexposed to inventory risk or cash flow strain.

Medium-volume assembly also gives companies more freedom to adapt. If demand spikes, production can be ramped up quickly without overhauling the entire supply chain. If the market shifts or product updates are required, the business doesn’t have to sit on warehouses full of obsolete boards. This balance of efficiency, scalability, and agility is exactly what makes medium-volume PCB runs so valuable for USA-based OEMs.

Just as importantly, medium-volume customers deserve and receive the same level of attention and technical support as any high-volume account. At Thomas Instrumentation, no client is treated as a “background task.” Our size allows us to dedicate meaningful engineering and production resources to every project. Each design, regardless of run size, is built with the same level of care, precision, and quality oversight that we apply to our largest customers.

The Risks of Going Overseas Too Early

Outsourcing production to overseas suppliers may look attractive on paper, but the reality is far more complicated. Lead times stretch into months, and shipping delays or customs issues can derail carefully planned product launches. Even when the product finally arrives, OEMs may face unexpected tariffs, quality concerns, or difficulties in securing recourse if something goes wrong.

These risks are amplified for companies that are just beginning to scale. An IoT business that suddenly has 5,000 defective boards sitting in a container halfway across the world may find its cash flow locked up and its reputation damaged. Communication barriers and time zone challenges only add to the frustration. For companies in industries where innovation cycles are fast and customer expectations are high, overseas outsourcing too early often proves more expensive than it first appeared.

The Advantages of Choosing a USA Electronics Supplier

By contrast, partnering with a USA-based electronics manufacturer removes many of these uncertainties. Faster turnaround times are a major advantage, as domestic suppliers can ship within days or weeks instead of months. The ability to collaborate directly with engineers in real time helps keep projects moving smoothly, especially when changes or troubleshooting are needed.

Quality is another critical factor. USA suppliers such as Thomas Instrumentation adhere to strict standards like ISO 9001:2015 and IPC-A-610, ensuring every board meets performance requirements. In sectors like industrial controls—where failures can mean regulatory penalties, equipment downtime, or safety risks—reliability and compliance aren’t optional. With a fully domestic supply chain, OEMs also avoid tariffs, shipping delays, and exposure to global instability.

Our company also stands apart through how we serve every customer with equal commitment, regardless of order size. Many large EMS providers focus their best resources on their highest-volume clients, leaving smaller or mid-range projects with minimal attention. At Thomas Instrumentation, we built our business model around the opposite approach. Medium-volume projects are not secondary—they are central to what we do. That means your 500–5000 unit production run receives full engineering engagement, proactive communication, and dedicated lifecycle support.

Industries That Benefit from Medium-Volume Assembly

Certain industries align especially well with the advantages of medium-volume PCB manufacturing. Appliance manufacturers often need boards for smart refrigerators, HVAC systems, or connected kitchen equipment, but their volumes don’t yet justify massive overseas orders. IoT developers face a similar situation when bringing smart thermostats, wearables, or security devices to market.

Industrial IoT and automation companies benefit from rugged, consistent boards that can be produced in scalable volumes as their smart factory solutions expand. Telecommunications and networking firms rely on dependable production runs for 5G routers, IoT gateways, and switches, where medium-volume production enables them to stay competitive without overcommitting. Meanwhile, renewable energy companies launching smart meters or solar controllers need predictable runs that allow them to refine products quickly as the market evolves. Test and measurement equipment manufacturers, too, find this range ideal, as it allows them to balance precision and scalability.

Each of these industries values agility, compliance, and cost-efficiency—making 500–5000 units per month an optimal choice. And with Thomas Instrumentation, those companies also gain something rare in the EMS world—personalized attention from a USA-based partner who views their success as equally important, regardless of production size.

Frequently Asked Questions About Medium-Volume PCB Assembly

Is medium-volume assembly cost-effective?

Yes. Once production reaches the 500–5000 unit level, OEMs begin to see meaningful cost reductions. At the same time, they avoid the risk of tying up capital in tens of thousands of units.

How does USA-based PCB manufacturing compare in cost?

While unit prices can be slightly higher than overseas, domestic assembly eliminates tariffs, reduces shipping costs, and minimizes quality issues. The total cost of ownership often comes out lower in the USA when all factors are considered.

Can medium-volume runs scale up if demand grows?

Absolutely. One of the greatest benefits of working with a USA-based supplier is the ability to increase production volumes quickly without reworking the supply chain.

What certifications should I look for?

OEMs should prioritize partners with ISO 9001:2015 and IPC-A-610 certifications. These ensure consistency, reliability, and compliance with industry standards.Learn more in our guide to enhancing product quality with ISO 9001:2015.

Why OEMs Trust Thomas Instrumentation

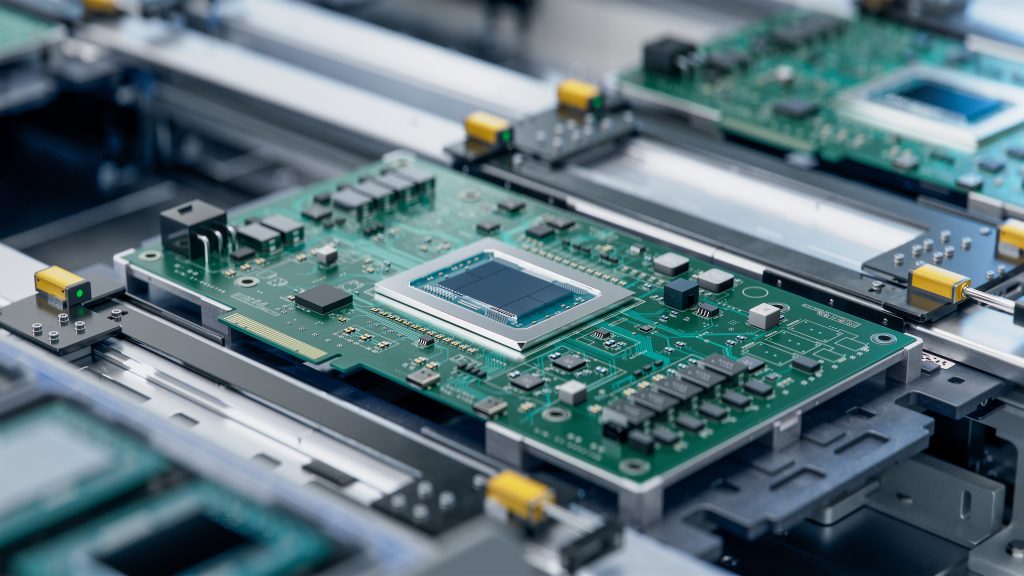

Located in Cape May Court House, NJ, Thomas Instrumentation focuses on the exact needs of companies requiring medium-volume PCB assembly. With over 50 years of experience in PCB design, embedded software, and electronics manufacturing, the team supports OEMs in appliances, IoT, telecommunications, and industrial automation.

Unlike high-volume global suppliers, Thomas Instrumentation specializes in runs of 500–5000 units per month, giving OEMs the balance of cost efficiency, quality, and flexibility they need to grow. What truly distinguishes our team is our commitment to treat every client—large or small—with equal importance. Our size allows us to be agile and responsive, ensuring mid-volume customers get direct access to the same engineering talent and quality systems as any major account. Every product we manufacture deserves optimal care, attention, and follow-through—because every customer’s success matters equally.

Our ISO-certified processes, IPC-compliant standards, and hands-on engineering expertise ensure that every project is delivered to the highest level of quality. By choosing Thomas Instrumentation, OEMs gain a USA-based partner that understands the importance of both technical precision and customer partnership.

Partner with Thomas Instrumentation

Medium-volume PCB assembly offers the agility, reliability, and scalability that OEMs in the USA need to move beyond prototyping without overcommitting to overseas suppliers. It is the ideal middle ground for companies building connected appliances, IoT devices, or industrial solutions, where quality and compliance are just as important as cost.

If your business is ready to scale production with confidence, contact Thomas Instrumentation today and start the conversation. Our team is ready to help you explore how medium-volume PCB manufacturing in the USA can support your next stage of growth—with the level of care and attention your products deserve.