Smart appliances are transforming both homes and commercial environments across the USA. From intelligent HVAC systems to connected kitchen devices, these innovations depend on one critical component: the custom-designed PCB layout that powers every function. For appliance OEMs, working with a trusted USA-based electronics supplier ensures reliability, compliance with industry standards, and the ability to scale production efficiently—while also unlocking access to the latest technologies and ensuring long-term durability.

Why Custom PCB Layouts Are Essential in Smart Appliances

Off-the-shelf circuit boards often fail to meet the complex needs of modern appliances. Smart refrigerators, ovens, and HVAC systems require designs optimized for specific functions—whether that’s sensor integration, connectivity, or durability. A custom PCB layout enables manufacturers to:

- Integrate advanced sensors for energy efficiency and safety.

- Support IoT connectivity, allowing appliances to communicate within smart homes.

- Maximize space efficiency inside compact housings.

- Enhance durability, ensuring boards withstand years of continuous operation.

In today’s competitive appliance market, these design choices aren’t optional—they define a product’s lifespan and reliability. At Thomas Instrumentation, our engineers also evaluate the longevity of every component used. We select high-quality, high-reliability parts with extended life ratings to ensure appliances operate for years without premature obsolescence.

Consumers today are increasingly frustrated that their washers, dryers, and refrigerators don’t last as long as they once did. Much of that disappointment traces back to lower-quality components and short-lived designs. Our approach eliminates that issue. By designing PCBs in the USA using up-to-date technologies and long-life components, we help manufacturers deliver appliances that maintain performance, reliability, and consumer trust over time.

The Risks of Relying on Overseas Suppliers

For procurement managers under pressure to manage costs, sourcing PCBs overseas may appear attractive. Yet when it comes to custom designs, the drawbacks quickly become clear. Shipping delays can disrupt launch timelines, tariffs add unexpected expenses, and quality control often falls short when oversight is limited.

What’s less obvious—but equally critical—is how foreign design restrictions limit the technology that can be used. Overseas engineers often rely on components that are nearing end-of-life (EOL) or technologies restricted under export controls. This means many offshore designs use outdated processors, sensors, and microcontrollers that soon become unavailable.

By contrast, U.S.-based design teams like Thomas Instrumentation have full access to the latest components and emerging technologies. This ensures not only cutting-edge performance, but also design stability and product longevity—vital factors for any appliance expected to operate reliably for a decade or more.

Communication challenges, time zone gaps, and weaker intellectual property protections add further complexity when working with overseas providers. For OEMs developing custom layouts that form the backbone of their appliances, these risks often outweigh the perceived cost savings of foreign suppliers.

A USA PCB supplier for appliances provides clear advantages:

- Access to the latest microcontrollers and sensor technologies unrestricted by export controls.

- Use of long-life, high-reliability components that prevent premature product obsolescence.

- Faster transitions from design to production.

- Real-time collaboration with engineers throughout the design and test process.

- Compliance with ISO 9001:2015 and IPC-A-610 standards.

- Stable, domestic supply chains that avoid international disruptions.

For OEMs bringing new smart appliances to market, these factors can determine whether a product becomes a trusted household brand or a short-lived, warranty-heavy liability.

Real-World Applications of Custom PCBs in Appliances

The value of custom PCB layouts becomes clearer when looking at how they are applied across key appliance categories:

HVAC Systems

Heating, ventilation, and air conditioning systems now feature smart connectivity and variable-speed controls. Custom PCBs regulate compressors, manage energy optimization, and link seamlessly with IoT thermostats. U.S.-designed boards ensure reliability, use modern components, and support long-term serviceability—so HVAC systems continue performing efficiently year after year.

Refrigerators and Freezers

Energy efficiency and component reliability are vital in refrigeration. Custom PCBs control compressors, defrost cycles, and data logging systems for energy management. Thomas Instrumentation designs boards using current-generation technologies and components with extended lifespans, ensuring these systems remain serviceable long after mass-market equivalents fail.

Ovens and Cooktops

Cooking appliances require precise control, timing, and safety management. A USA-designed custom PCB ensures seamless communication between temperature sensors, user interfaces, and connected devices. With careful component selection, these boards sustain accuracy and performance over a long operational life, minimizing failure rates.

Dishwashers and Laundry Machines

Washers, dryers, and dishwashers depend on boards that coordinate cycles, monitor loads, and optimize water and energy consumption. Unfortunately, many imported control boards use short-lifecycle components that fail early or become obsolete within a few years. Thomas Instrumentation eliminates that concern by specifying high-endurance parts designed for longevity—so customers experience reliability closer to what appliances once delivered decades ago.

Commercial Appliances

For commercial kitchens, laundromats, and industrial cleaning systems, reliability is non-negotiable. Custom PCBs enable manufacturers to integrate advanced control functions while using durable, heat- and moisture-resistant materials. By designing and building in the U.S., OEMs can maintain high operational uptime and reduce maintenance costs across the lifespan of their equipment.

Key Considerations for Procurement Managers

When choosing a supplier for custom PCB layouts, procurement leads should look beyond initial pricing and consider:

- Design Expertise: Engineering teams experienced in appliance-specific layouts and reliability design.

- Scalability: Production capacity for medium-volume runs (typically 500–1000 units per month).

- Compliance: ISO 9001:2015 certification and IPC-A-610 workmanship standards.

- Longevity and Reliability: Use of long-life, high-quality components to extend appliance lifespan.

- Technology Access: Freedom from export restrictions and access to the newest component families.

- Integration Support: Expertise in embedded software and IoT connectivity.

Selecting a U.S.-based partner with these capabilities ensures not only product quality but also stability, predictability, and extended service life—key considerations in today’s competitive appliance market.

Frequently Asked Questions

Why not use generic boards for appliances?

Generic boards may reduce initial costs, but they rely on limited technology and cannot deliver the long-term reliability consumers expect. Custom PCBs allow engineers to select the latest components and optimize designs for performance and lifespan.

How do medium-volume runs support appliance OEMs?

Medium-volume runs of 500–1000 units per month provide enough scale to reduce unit costs while allowing companies to adapt quickly to changes in technology or consumer demand.

Is domestic manufacturing really more cost-effective?

Yes. While per-unit costs may appear higher, domestic manufacturing eliminates tariffs, reduces logistics costs, and prevents expensive redesigns caused by overseas component obsolescence.

Can U.S.-based suppliers integrate the latest technologies?

Absolutely. Working with a U.S. partner allows OEMs to adopt cutting-edge sensors, processors, and connectivity standards that foreign suppliers often can’t access due to export limitations.

The Future of Smart Appliances and PCB Innovation

Smart appliances continue to evolve through IoT integration, energy efficiency mandates, and growing consumer expectations for durability. U.S.-based PCB design and manufacturing give OEMs the freedom to integrate the latest component technologies while ensuring that every product remains serviceable and reliable for years.

Consumers increasingly value appliances that last—and domestic design plays a major role in achieving that. By designing with long-lifecycle components, robust materials, and forward-compatible architectures, manufacturers can restore consumer confidence in product quality and longevity.

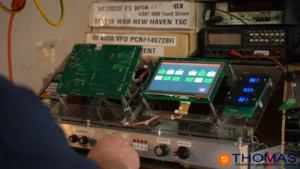

Why OEMs Partner with Thomas Instrumentation

Located in Cape May Court House, NJ, Thomas Instrumentation specializes in custom PCB layouts, embedded software, and medium-volume electronics manufacturing for OEMs across the USA. With decades of experience, the company provides solutions that combine modern component technology, reliability engineering, and design for longevity.

Services include:

- Custom PCB design optimized for HVAC, refrigeration, and smart kitchen appliances.

- Embedded software for connectivity and advanced control.

- ISO 9001:2015 certified processes and IPC-A-610 compliant workmanship.

- Medium-volume production (500–1000 units/month) for efficient scalability.

- Component selection focused on long life, high reliability, and technology currency.

By choosing Thomas Instrumentation, OEMs gain a partner that doesn’t just design for performance—but for product endurance. Our boards are built to help appliances last longer, perform better, and maintain value over time.

Partner with Thomas Instrumentation

Appliance OEMs face growing pressure to deliver smarter products that also stand the test of time. Relying on generic PCBs or overseas suppliers limits design capability, introduces outdated technology, and shortens product lifespan. Custom PCB layouts designed and built in the USA provide the compliance, durability, and innovation needed for long-term success.

If your company is ready to elevate its appliance line with reliable, forward-thinking PCB designs, contact Thomas Instrumentation today. Our engineers are ready to help you design electronics that power the next generation of smart, long-lasting appliances.