Power tools are expected to perform under conditions that would quickly destroy conventional electronics. From job sites filled with dust and vibration to temperature swings and electrical stress, the environments surrounding modern power tools are unforgiving. For tool manufacturers focused on reliability, safety, and long service life, rugged electronics are no longer optional. Thomas Instrumentation works with manufacturers to ensure that USA-made are built on durable, well-engineered PCB assemblies designed to withstand these harsh realities.

Whether supporting cordless drills, industrial fastening tools, or diagnostic-enabled smart tools, rugged PCB design plays a central role in ensuring consistent performance. This article explores how PCB manufacturing in the USA addresses durability challenges and why robust electronics are essential for today’s power tool industry.

Why Power Tool Electronics Face Unique Challenges

Harsh Operating Conditions Are the Norm

Unlike consumer electronics that operate in controlled indoor environments, power tools are routinely exposed to:

- Dust, debris, and metal shavings

- Repeated shock and vibration

- Moisture, humidity, and condensation

- Extreme hot and cold temperatures

- Electrical noise from motors and batteries

According to IPC guidelines on electronics reliability, mechanical stress and environmental exposure are among the leading causes of PCB failure in industrial equipment. Power tools experience all of these stressors simultaneously, making durability a foundational design requirement rather than an enhancement.

Increasing Electronic Complexity in Tools

Modern power tools are no longer purely mechanical. Electronics now support:

- Battery management systems

- Motor control and efficiency optimization

- Embedded diagnostics and fault detection

- Connectivity for smart tools and fleet management

- Safety features such as overload protection

As functionality increases, so does reliance on robust circuit board design. A single PCB failure can disable an entire tool, impacting productivity and brand reputation.

The Role of Rugged PCB Design in Power Tools

Mechanical Durability and Shock Resistance

One of the most critical requirements for power tool electronics is resistance to shock and vibration. Tools are dropped, jarred, and subjected to constant movement during operation.

Rugged PCB design strategies include:

- Thicker PCB substrates to improve rigidity

- Secure component anchoring to prevent movement

- Strategic placement of heavy components

- Reinforced solder joints to withstand fatigue

In USA-based facilities, tighter process control allows manufacturers to reduce variation that could weaken solder joints or introduce stress points.

Thermal Management Under Load

Power tools generate heat — both from motors and from high-current electronics. Without proper thermal design, excessive heat can shorten component life or cause immediate failure.

Durability-focused thermal strategies include:

- Heat-resistant PCB materials

- Adequate copper thickness for current handling

- Optimized trace routing to reduce resistance

- Controlled airflow within tool housings

The U.S. Department of Energy notes that thermal stress is a major contributor to electronic component degradation, especially in high-power applications like motor-driven tools.

PCB Materials That Support Durability

Substrate Selection for Harsh Environments

Standard FR-4 materials may not always be sufficient for demanding tool applications. Manufacturers often evaluate higher-performance materials based on operating conditions.

Material considerations include:

- Higher glass transition temperature (Tg) for heat resistance

- Improved moisture resistance

- Enhanced mechanical strength

Selecting the right substrate helps ensure stability across temperature swings and prolonged use.

Copper Weight and Power Handling

Power tools often require PCBs capable of handling significant current, particularly in cordless tools where battery output must be managed efficiently.

Heavier copper layers provide:

- Lower resistance and reduced heat buildup

- Improved durability of power traces

- Greater tolerance for electrical surges

USA-based power tool circuit board manufacturing allows for tighter control over copper thickness and layer consistency.

Environmental Protection for Tool Electronics

Conformal Coating and Encapsulation

Dust, moisture, and contaminants can quickly compromise exposed electronics. Protective coatings are commonly used to extend PCB life.

Environmental protection methods include:

- Conformal coatings to shield against moisture and debris

- Selective coating to protect sensitive areas

- Encapsulation for extreme conditions

These protective measures are especially valuable for tools used outdoors or in industrial environments.

Designing for Ingress Protection

While housings provide the first line of defense, internal electronics must still be prepared for exposure. Rugged PCB design assumes that some level of environmental intrusion will occur over time.

Design strategies focus on:

- Minimizing exposed conductive areas

- Strategic placement of connectors

- Reducing corrosion risk through material choice

Electronics for Smart and Diagnostic Power Tools

The Rise of Smart Tools

Electronics for smart tools introduce new reliability considerations. Embedded sensors, communication modules, and microcontrollers must operate reliably alongside high-power components.

Smart tool electronics often support:

- Usage tracking and diagnostics

- Wireless connectivity

- Predictive maintenance alerts

- Performance optimization

These features increase value for tool manufacturers but also raise expectations for PCB reliability.

Diagnostics Depend on Electronic Stability

Diagnostic tools embedded within power tools rely on accurate data collection. Signal integrity issues caused by vibration, electrical noise, or poor layout can undermine these capabilities.

Durable PCB design supports:

- Noise-resistant signal routing

- Stable reference voltages

- Shielding from motor interference

From first-hand experience in electronics manufacturing, unreliable diagnostics are often traced back to insufficient isolation between power and control circuits.

The Advantage of USA-Based PCB Manufacturing

Consistency and Quality Control

Durability begins with consistent manufacturing. USA-based facilities typically operate under stricter quality systems, reducing variability that can weaken PCB assemblies.

Key advantages include:

- Controlled process environments

- Comprehensive inspection and testing

- Faster feedback between design and production

These factors are critical when building electronics expected to perform under stress.

Collaboration on Rugged Design

Domestic manufacturing enables closer collaboration between tool designers and electronics assemblers. Early design involvement helps address durability challenges before production begins.

Collaboration supports:

- Design for manufacturability (DFM)

- Design for reliability (DFR)

- Faster iteration and validation

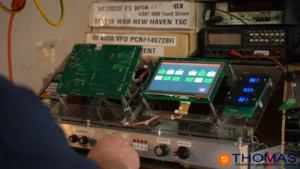

Thomas Instrumentation works alongside tool manufacturers to ensure rugged design principles are applied throughout the product lifecycle.

Reliability Testing for Power Tool Electronics

Testing Beyond Basic Functionality

Durable electronics require more than functional testing. Reliability-focused testing simulates real-world conditions that power tools will encounter.

Common tests include:

- Thermal cycling

- Vibration and shock testing

- Electrical stress testing

- Environmental exposure simulations

IPC standards emphasize that environmental testing is essential for products intended for industrial or field use, including power tools.

Preventing Field Failures

Field failures are costly — not just in repairs, but in warranty claims and brand damage. Proactive testing helps identify weak points before tools reach customers.

Manufacturers that invest in rigorous testing often experience:

- Lower warranty costs

- Improved product reputation

- Longer tool lifespans

Designing for Serviceability and Longevity

Repair-Friendly PCB Design

Power tools are often repaired rather than discarded, especially in professional environments. PCB design that supports serviceability improves both sustainability and customer satisfaction.

Repair-friendly considerations include:

- Accessible test points

- Modular PCB assemblies

- Durable connectors that withstand multiple service cycles

These design choices align durability with long-term value.

Supporting Product Longevity

Reliable electronics allow tools to remain in service longer, reducing replacement frequency and supporting sustainability goals. Durable PCB assemblies contribute directly to extended product life.

From an industry perspective, tools that last longer strengthen brand trust and reduce total cost of ownership for users.

What Tool Manufacturers Should Prioritize

When evaluating electronics partners for power tool applications, manufacturers should consider:

- Experience with rugged PCB design

- Understanding of harsh operating environments

- USA-based manufacturing capabilities

- Proven quality and testing processes

- Ability to support both standard and smart tool electronics

Thomas Instrumentation focuses on aligning electronics durability with real-world tool performance requirements.

FAQs About Power Tool Electronics Durability

1. Why are power tool PCBs more prone to failure than consumer electronics?

Power tools operate in harsher environments with higher vibration, dust, and electrical stress, which increases failure risk without rugged design.

2. What materials improve PCB durability for power tools?

Higher-Tg substrates, heavier copper layers, and protective coatings all contribute to durability in demanding applications.

3. How do smart tool electronics change durability requirements?

Smart tools add sensitive control and communication circuits that must be protected from electrical noise and mechanical stress.

4. Does USA-based PCB manufacturing improve reliability?

Domestic manufacturing often provides better quality control, faster collaboration, and more consistent results for rugged applications.

5. Can durable PCB design reduce warranty costs?

Yes. Fewer field failures lead to lower warranty claims and improved customer satisfaction.

Building Power Tools That Last

Durability is not an afterthought in power tool electronics — it is a defining requirement. From cordless drills to advanced diagnostic-enabled tools, rugged PCB design ensures reliability under constant stress. As power tools become more electronic and more intelligent, the need for well-engineered, USA-manufactured circuit boards continues to grow.

By partnering with Thomas Instrumentation, tool manufacturers gain access to electronics expertise focused on durability, consistency, and real-world performance. Strong electronics are what keep power tools running when conditions are toughest — and that reliability is what end users trust.