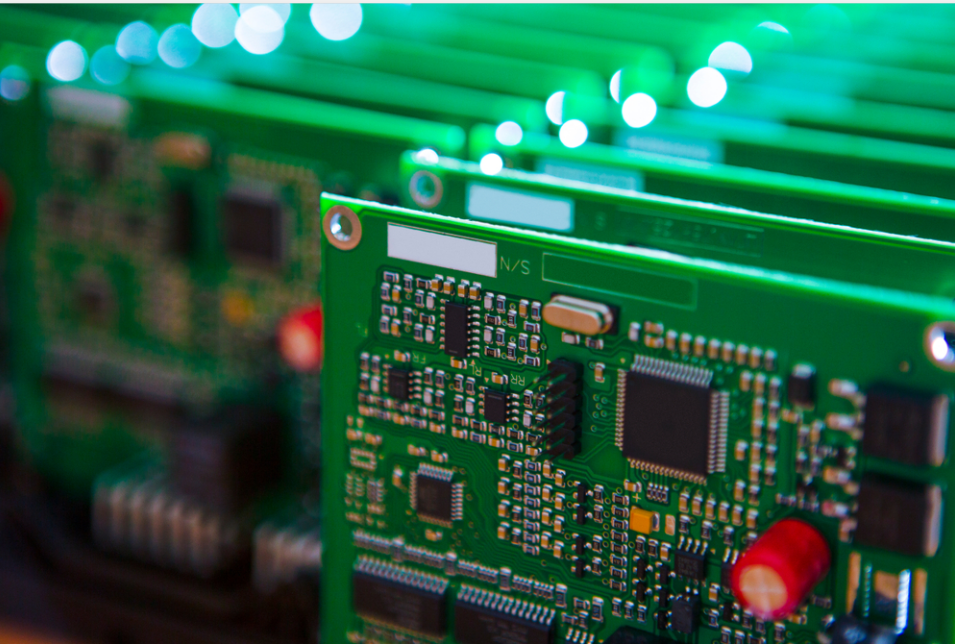

Thomas Instrumentation turns complex ideas into manufacturable PCB designs. We handle schematic development, layout, prototyping, and full lifecycle support with an emphasis on custom design, Design for Manufacturability (DFM), rapid validation, and reliable, high-quality engineering.

Revitalizing existing PCB designs to meet modern standards, ensuring compatibility, efficiency, and longevity. This includes component obsolescence planning, footprint updates for current supply chains, and touch screen interface upgrades.

Utilizing advanced technology and methods to engineer dependable and innovative electronic solutions.

Discovery & Requirements Capture

Defining specifications, risks, performance targets, and compliance needs.

Schematic & Library Preparation

Creating verified symbols and footprints, setting design rules, and building a clean documentation foundation.

Prototype & Bring-Up

Developing test strategies, validating functionality, and performing structured debugging.

Lifecycle Support

Managing engineering change orders (ECOs), incorporating field feedback, and supporting modernization or refurbishment throughout the product’s life.

Thomas Instrumentation delivers custom embedded systems and PCB designs for all industries, with a specialty in high-reliability, high-quality engineering.

We provide:

Flexible solutions for any application or sector

Designs built for longevity, consistency, and long-term production needs

Full lifecycle support from concept through modernization

Our versatility allows us to meet the needs of diverse clients without limiting ourselves to specific industry categories.

Decades of extensive experience in PCB design across diverse industries.

Tailored solutions expertly crafted to meet your specific project requirements.

Comprehensive and rigorous testing, quality control for every design.

A commitment to incorporating the latest technology and innovations.