Successful PCB design for renewable energy products requires early design-for-manufacturing (DFM) collaboration, careful material selection suited for harsh environments, attention to safety compliance requirements, and partnerships with U.S.-based mid-volume PCB manufacturers offering engineering input and production agility.

The Growing Need for Specialized PCB Design in Renewable Energy

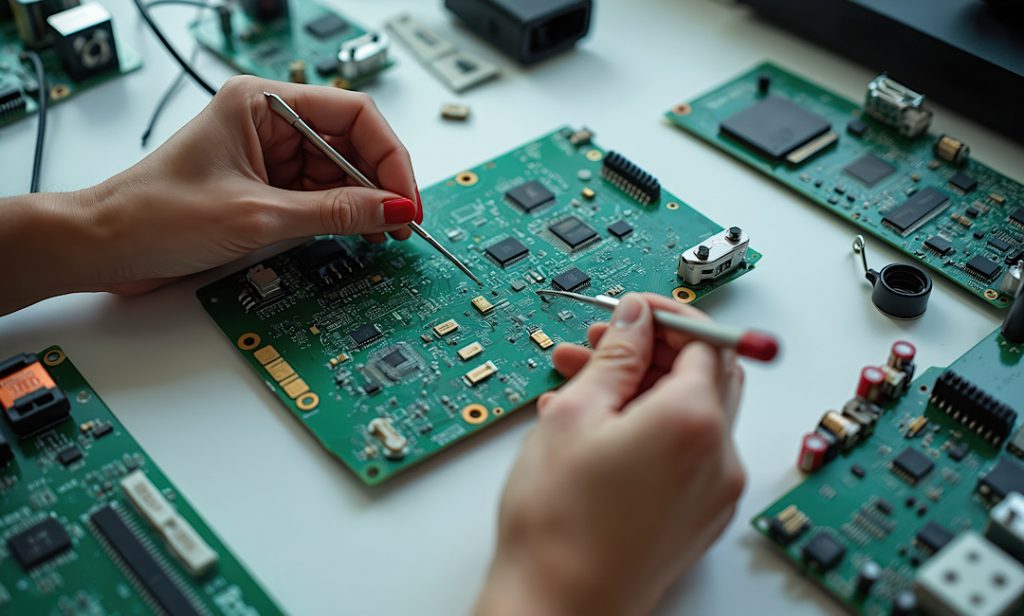

As solar, wind, and grid modernization technologies evolve, printed circuit boards (PCBs) are becoming more essential—and more complex. Renewable energy systems now include components like inverters, battery management systems, power converters, and control modules that rely on intricate circuitry. These systems incorporate high-voltage handling, real-time monitoring, power regulation, and sensor integration—each of which increases the complexity and sensitivity of PCB design.

Products in this space often require PCBs that can carry high current loads and withstand extreme conditions such as heat, vibration, humidity, and dust. Compounding these demands is the mid-volume nature of renewable energy production, with annual production runs typically ranging from thousands to tens of thousands of units. That puts a premium on PCB partners who can balance manufacturing consistency with scalable production.

Many companies in this space have found that offshore suppliers fall short when it comes to providing the engineering collaboration and manufacturing precision required. U.S.-based mid-volume PCB manufacturers fill this gap, offering both speed and quality control necessary for renewable energy hardware development.

Design-for-Manufacturing (DFM) Starts at the Concept Stage

One of the most common missteps in renewable energy product development is waiting too long to engage manufacturing partners. Deferring DFM input until after a design is complete can result in costly iterations and preventable production delays. Early-stage DFM collaboration helps optimize circuit layouts for manufacturability from the outset.

- Renewable energy design teams should take the following into account during early development:

- Trace widths and spacing are appropriate for high-current environments

- Thermal management strategies for components exposed to constant heat

- Controlled impedance for accurate communication signaling

- Board stack-up strategies that optimize power and signal layer separation

- Component placement that supports automated assembly lines

Collaborating with domestic PCB manufacturers like Thomas Instrumentation enables these discussions to happen early in the process. With direct access to engineering resources, potential manufacturability issues can be resolved before they escalate—keeping projects on schedule and within budget.

Material Selection is Critical for Harsh Operating Conditions

Renewable energy PCBs must endure environmental extremes. Outdoor installations—such as wind turbines and solar panels—must tolerate UV radiation, temperature fluctuations, moisture, and vibration for 10 to 20 years. Selecting the right laminate and substrate materials ensures long-term durability.

While FR-4 remains common, high-performance materials like polyimide or high-Tg laminates offer enhanced thermal and moisture resistance. Material decisions should be based on:

- Expected operating temperature range

- Power density and required heat dissipation

- Humidity exposure and moisture resistance

- Electrical load performance and stability

These criteria apply broadly across industries that require rugged and thermally stable PCBs—not just renewable energy. PCB manufacturers like Thomas Instrumentation help customers navigate these specifications to support high-reliability applications.

Meeting Industry Safety and Certification Requirements

Renewable energy PCBs often interface with high-voltage systems, requiring stringent design practices to comply with safety standards. While product-specific certifications like UL or IEC are customer-led, manufacturers must understand how to build to those standards.

U.S.-based PCB manufacturers ensure quality by adhering to:

- IPC-A-610 for electronic assembly acceptability

- ISO 9001 for quality management systems

- Industry best practices for safety-critical designs

Rather than handling certification themselves, manufacturers like Thomas Instrumentation support customers by building compliant boards and collaborating closely during testing and verification phases.

Mid-Volume PCB Manufacturing Balances Flexibility and Scale

Many renewable energy companies struggle to find PCB manufacturers who can balance technical capability with appropriate scale. Low-volume shops may not have the engineering expertise, while high-volume contract manufacturers often lack the flexibility for rapid iteration.

Mid-volume production—ranging from thousands to tens of thousands of units annually—requires:

- Quick-turn prototyping for early-stage R&D

- Scalable production processes that avoid quality variation

- Direct engineering communication for efficient design changes

- Reliable lead times without the uncertainty of international logistics

By working domestically, renewable energy OEMs maintain visibility and control over their production timelines, while minimizing the risks of overseas shipment delays.

Protecting Intellectual Property and Mitigating Cybersecurity Risks

As renewable energy systems become more connected, the stakes for protecting intellectual property and ensuring cybersecurity rise dramatically. Devices like solar inverters increasingly contain embedded firmware and communication modules that, if compromised, could expose national infrastructure.

The U.S. Department of Energy and cybersecurity watchdogs have expressed concern over overseas-produced power electronics. For example, some imported inverters have included undocumented communications hardware that could theoretically allow remote manipulation. In a worst-case scenario, compromised firmware could allow a foreign entity to disable or interfere with critical power infrastructure.

Producing PCBs domestically keeps sensitive technology within secured facilities and protects:

- Firmware encryption routines

- Proprietary control algorithms

- Sensor calibration sequences

- Power grid integration protocols

The risk is no longer hypothetical. As a national security issue, moving production onshore helps prevent adversaries from exploiting backdoor vulnerabilities embedded in offshore components. For companies designing renewable energy technology, this has become a priority—not just an option.

Cost Advantages Beyond the Price Per Board

While offshore PCB prices may appear cheaper on a per-board basis, they rarely reflect the total cost of ownership. When factoring in rework, shipping delays, quality inconsistencies, and IP risk, the long-term financial burden of overseas production often surpasses the upfront savings.

According to the Reshoring Initiative’s 2023 report, 46% of U.S. companies reduced total costs by moving electronics manufacturing back to the United States. For renewable energy products with expected 10–20 year field lifespans, the true cost of a failure far outweighs a minor difference in board pricing.

Federal Policies Are Driving Domestic Manufacturing Growth

Recent federal legislation is helping accelerate this shift. The 2022 CHIPS and Science Act allocated $52 billion in funding to strengthen domestic electronics production. Alongside broader clean energy initiatives, this reflects growing national interest in:

- Securing clean energy technology supply chains

- Creating and retaining high-skill manufacturing jobs

- Reducing reliance on foreign electronics

Equally important is protecting the grid from embedded threats. Domestic PCB production helps ensure that critical components are free from foreign-installed hardware that could compromise system control or create national vulnerabilities.

Thomas Instrumentation Supports Renewable Energy PCB Development

Thomas Instrumentation provides U.S.-based, full-service PCB assembly tailored to demanding mid-volume applications. While its primary experience is in other industrial sectors, the company’s capabilities—including design collaboration, complex board assembly, and thermal management strategies—are fully suited to support renewable energy OEMs.

Services include:

- Engineering collaboration during early design

- Advanced multilayer PCB fabrication

- High-current handling and thermal management strategies

- Surface mount and through-hole assembly

With a strong track record in producing complex circuit boards with tight tolerances, Thomas Instrumentation is well-positioned to support companies entering or expanding in the renewable energy space. The team’s ability to combine agile manufacturing processes with in-depth engineering guidance helps clients reduce risk, accelerate development, and meet performance demands.

Ready to Build Smarter Renewable Energy Hardware?

Please fill out the form on our Contact Page to get started on your next renewable energy hardware project.