U.S.-based medium-volume PCB manufacturing gives smart tool companies the flexibility to innovate faster, reduce lead times, maintain superior quality, and secure reliable production — without the risks and delays of offshore sourcing.

The Growing Complexity of Smart Tool Electronics

Smart tools are evolving rapidly. Power tools, diagnostic devices, and industrial equipment increasingly integrate sensors, wireless modules, microcontrollers, and advanced user interfaces. This complexity makes the role of the printed circuit board more critical than ever. As companies race to release smarter, more connected tools, their manufacturing challenges also multiply.

Unlike mass consumer electronics or one-off prototypes, smart tools often require medium-volume PCB production — runs that range from hundreds to tens of thousands of units. This volume sweet spot demands a manufacturing partner who can balance agility with scalability.

For many tool manufacturers, global supply chains are no longer able to meet this balance. Long lead times, communication delays, and inconsistent quality make offshore PCB suppliers risky for smart tool production, where timing and precision are everything.

How Global Delays Threaten Smart Tool Development

Relying on overseas PCB suppliers often means accepting production cycles that are vulnerable to:

- Ocean freight delays and port congestion

- Customs clearance issues

- Unpredictable shipping costs

- Time zone misalignments that slow communication

According to IPC’s 2024 Global Electronics Supply Chain Survey, 84% of electronics manufacturers experienced serious delivery disruptions over the past two years. For companies working on tight product release schedules, these delays can derail launches and hurt revenue streams.

However, Thomas Instrumentation successfully avoided these delays through strategic forecasting, adaptable sourcing, and an established domestic vendor network — a distinction that has earned the trust of many across all industries.

As Thomas team member Cassandra Gluyas notes:

“We did not have any delays due to our unique ability to forecast, adapt designs, and maintain a flexible vendor network.”

Domestic PCB manufacturing helps eliminate these pain points. By keeping production close to home, smart tool manufacturers can stay in control of delivery timelines and reduce risk across their production pipeline.

Medium-Volume PCB Assembly Delivers Flexibility and Speed

Medium-volume PCB production excels when flexibility is key. Smart tool makers often need to prototype, refine, and scale quickly without committing to massive production runs. U.S.-based PCB partners like Thomas Instrumentation allow manufacturers to iterate rapidly while still supporting ramp-ups into higher volumes when demand increases.

Manufacturers benefit from:

- Shorter lead times — often cutting delivery from months to weeks

- Faster design feedback through direct engineering collaboration

- Agile adjustments when design changes occur mid-production

- Controlled inventory levels that reduce carrying costs

With the right domestic partner, smart tool companies can keep their development cycles nimble while maintaining the flexibility to scale production as sales grow.

Quality and Reliability Set Domestic PCB Manufacturing Apart

Smart tools operate in harsh environments and require electronics that perform flawlessly. Vibration, dust, moisture, and temperature extremes place constant stress on tool circuitry. A single PCB defect can lead to product failure, customer dissatisfaction, and warranty costs.

U.S.-based PCB assembly provides higher quality assurance through:

- Compliance with IPC-A-610 and ISO 9001 standards

- Real-time inspections during assembly

- Automated optical inspection (AOI) and X-ray verification

- Full lot traceability for every production run

According to the National Institute of Standards and Technology (NIST), domestic PCB defect rates are 40–55% lower than offshore manufacturing. At Thomas Instrumentation, the bar is even higher — their defect rate is consistently below 1%.

“We perform full root-cause failure analysis on any defect. Our goal is to deliver 100% functional, field-ready boards.” — Cassandra Gluyas, Thomas Instrumentation

This attention to quality translates to fewer warranty claims, greater customer satisfaction, and long-term performance that manufacturers can trust.

Domestic PCB Assembly Simplifies Compliance and Protects Intellectual Property

As smart tools become more advanced, protecting intellectual property becomes increasingly important. Firmware, software algorithms, calibration routines, and wireless communication protocols are valuable assets. Offshore manufacturing increases exposure to unauthorized duplication and IP theft.

By working with a U.S.-based partner like Thomas Instrumentation, manufacturers can:

- Minimize IP theft and duplication risks

- Ensure compliance with U.S. cybersecurity standards like NIST SP 800-171 and CMMC

- Navigate U.S. environmental and hazardous material regulations with confidence

With export-controlled technologies becoming more common in commercial smart tools, working with a domestic partner also ensures eligibility for the latest components without regulatory restrictions.

Total Cost of Ownership Favors Domestic Manufacturing

Although overseas PCB unit prices may appear cheaper at first glance, the real cost story tells a different tale. When factoring in:

- Freight and customs fees

- Rework and scrap costs

- Communication delays

- Longer lead times

- Inventory carrying costs

…domestic production often proves more cost-effective in the long run.

A 2023 Reshoring Initiative report found that 46% of U.S. manufacturers lowered total production costs after moving PCB assembly back home. Predictable pricing and fewer disruptions make U.S.-based medium-volume manufacturing a smart financial strategy for growing tool brands.

Federal Support Further Strengthens Domestic Manufacturing

The 2022 CHIPS and Science Act allocated $52 billion to revitalize American semiconductor and electronics production. This federal investment reinforces the strategic value of reshoring electronics to support both national security and long-term industrial competitiveness.

Tool manufacturers that prioritize domestic PCB sourcing are helping to strengthen U.S. infrastructure while also benefiting from a stronger, more responsive supply chain.

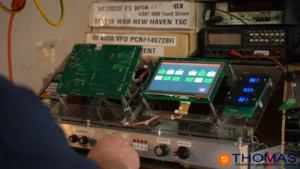

Thomas Instrumentation’s Role in Smart Tool Innovation

Thomas Instrumentation specializes in U.S.-based medium-volume PCB assembly tailored for smart tool companies. From sensor modules to wireless control boards and embedded processors, their team offers:

- Multilayer PCB fabrication with advanced material options

- Surface mount technology (SMT) precision placement

- Embedded firmware programming and functional testing

- Engineering support that bridges design and manufacturing

- Lifecycle support through repairs

By partnering with Thomas Instrumentation, smart tool OEMs gain a domestic manufacturing resource that prioritizes quality, flexibility, and responsiveness.

Whether you’re scaling production for a new product launch or need help refining your board design for manufacturability, Thomas Instrumentation delivers the precision and reliability smart tools demand.

Ready to Accelerate Your Smart Tool Innovation?

Please fill out the form on our Contact Page to get started with your next project.