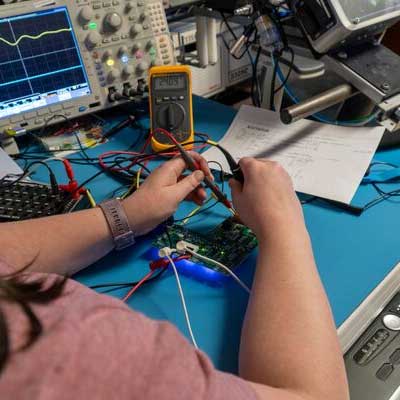

Design & Engineering

As our history and industry pages indicate, we have engineered a wide variety of products using many different technologies. Our major fields of expertise include precision analog, digital, and industrial control circuitry. Some of our popular technologies today are Touch Screens, Internet of Things (IoT), and Power Solutions (solar, batteries, etc.). If you’re looking for a specific technology, then please see our extended list of expertise by either scrolling below or clicking here. When it comes to engineering design, Thomas Instrumentation typically sees three different project types:

New Product Design

In this case, Thomas Instrumentation steps into the design process early in the customer’s project concept phase. Our engineers work hand-in-hand with the customer to review requirements, make suggestions, and develop the best design concept for the project. Some of our past suggestions have included items such as firmware upgradeability, future expansion capabilities (extra inputs/outputs, etc.), parts availability and cost, and more effective methods to complete functions. Once the design requirements are finalized, our engineers develop the schematics necessary for turning the design into hardware.

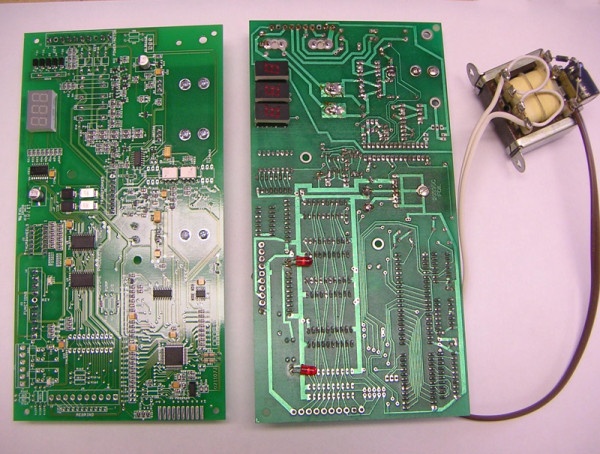

Upgrading Obsolete or Older Products

Almost every customer selling technology products have experienced the dreaded problem of obsolete parts or old technology. Thomas Instrumentation has been around since the first microprocessors were released, so our engineers are well-practiced at upgrading and altering designs. We work with our customers to make any changes they require. Some typical reasons for change include but are not limited to increasing functionality, converting Thru-hole designs to surface mount technology, increasing efficiency, reducing hear, reducing size, increasing reliability, and adding protection circuitry. Whatever your reasoning for change may be, we can help.

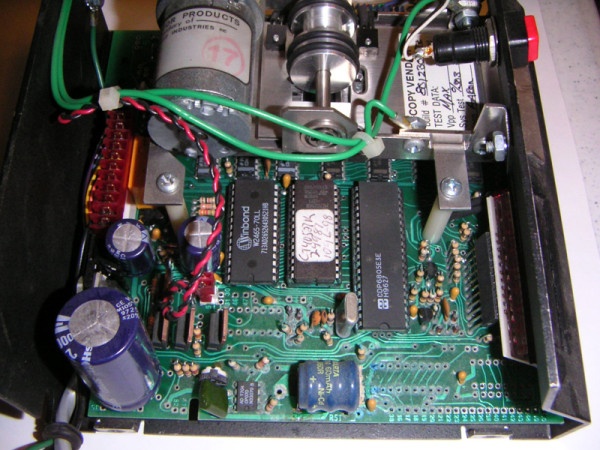

Reverse Engineering

Another common problem we see is customers whose original product manufacturer went out of business and did not provide the customer with their documentation. These cases are time-consuming, but usually not impossible if we have a board to reverse engineer and documentation on what functions it performs. From that, our electrical engineers work hand-in-hand with our PCB designer to carefully trace all of the circuitry. Once the board has been fully traced, we develop official schematics and a PCB layout in our system. This way we can manufacture more product and support any existing units. During this time, many customers also ask to update their product.

We are confident in our ability to engineer a successful product for you no matter what kind of technology your concept requires. The following is good overview of our technology expertise: