Prototyping

Thomas Instrumentation firmly believes in the need to fully test hardware before moving a design into production. To uphold this belief and ensure our final products are the best, we urge customers to invest in the prototyping phase of a project. Upon the validation of the prototypes and the approval of the client, the product is ready to be put into mass production. Our prototyping service typically comes in the following two forms:

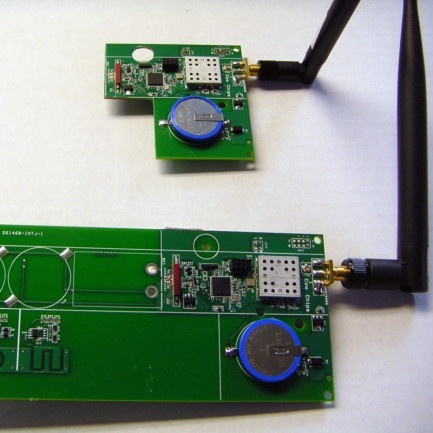

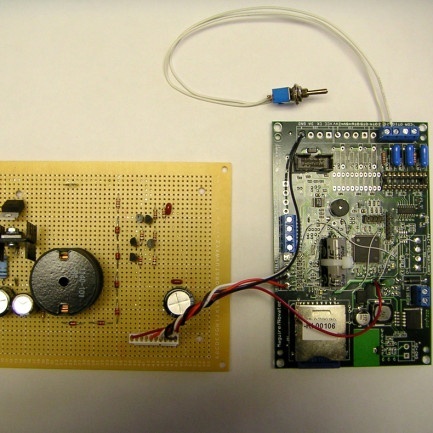

Proof of Concept

These prototypes are manufactured several different ways depending upon the complexity of a design and the portion of circuitry that requires testing. At times, we have customers who do not want to invest a lot of time and money in a project concept that may not work for their intended application. In these cases, we develop a simple prototype that performs only the most basic functions to prove the customer’s idea. This type of prototype can be anything from a simple breadboard circuit to a modified version of an in-house production board.

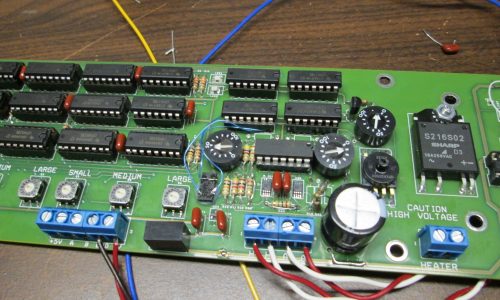

Pre-Production

These prototypes are manufactured for us by a board production house with a quick turn-around time. They are typically a small quantity of 3 to 10 boards and are the first batch created from our PCB Gerber files. The prototype boards are run through our standard production process which serves to verify our procedures for this product. If there are any problems with the process, we correct them at this time.

Once complete, these prototypes are subjected to thorough testing that checks for heat issues, ESD/noise issues, software bugs, environmental survivability, and much more. If the boards survive our internal tests, then we ship them off to our customer. The customer then runs the boards through their own tests which better simulate actual operating conditions of the product. If the prototypes pass muster for both of us, then the product is ready to move into mass production.