As sustainability moves from a corporate value to a business requirement, electronics manufacturers are being challenged to rethink how products are designed, built, maintained, and reused. In the United States, this shift is especially visible in printed circuit board (PCB) assembly, where environmental impact intersects with precision manufacturing. For organizations working with Thomas Instrumentation, sustainability is no longer just about compliance — it is about long-term efficiency, brand responsibility, and resilience in the supply chain.

Environmentally focused OEMs are increasingly asking the same question: How can PCB assembly be more sustainable without sacrificing performance, reliability, or scalability? The answer lies in a combination of eco-friendly manufacturing processes, smarter material choices, waste reduction strategies, and a renewed emphasis on repair and refurbishment rather than disposal.

This article explores how sustainable PCB assembly is evolving in USA-based facilities and what it means for forward-thinking electronics manufacturers.

Why Sustainability Matters in PCB Assembly Today

Electronics Manufacturing and Environmental Impact

Electronics manufacturing has traditionally carried a heavy environmental footprint. According to the U.S. Environmental Protection Agency, electronics waste is one of the fastest-growing waste streams in the country, with millions of tons generated annually. PCBs contribute significantly to this problem due to their complex mix of metals, laminates, chemicals, and solder materials.

PCB assembly impacts the environment in several key ways:

- Energy-intensive production processes

- Chemical usage in cleaning and surface finishing

- Scrap boards and defective assemblies

- Short product life cycles lead to premature disposal

As sustainability expectations rise across industries — from medical devices to industrial controls — OEMs are under pressure to align their electronics manufacturing with environmental goals.

The Role of USA-Based Manufacturers

Domestic PCB assembly facilities play a critical role in sustainability. Manufacturing in the USA often allows for:

- Stricter environmental regulations and oversight

- Shorter supply chains that reduce transportation emissions

- Better quality control, reducing scrap and rework

- Easier collaboration on design-for-sustainability initiatives

For companies like Thomas Instrumentation, supporting eco-friendly electronics manufacturing means working closely with OEMs to optimize both the production process and the full lifecycle of the product.

Core Principles of Sustainable PCB Assembly

1. Waste Reduction Through Smarter Design

Sustainability starts long before the first board is assembled. Design decisions have a direct impact on waste generation.

Key waste-reduction strategies include:

- Design for Manufacturability (DFM): Reducing assembly errors lowers scrap rates.

- Panel optimization: Efficient panel layouts minimize unused board space.

- Component standardization: Fewer unique parts reduce excess inventory and obsolescence.

Industry studies show that up to 70% of manufacturing waste can be traced back to design decisions, making early collaboration between OEMs and assembly partners essential.

2. Lead-Free and Environmentally Safer Materials

One of the most visible sustainability shifts in PCB assembly has been the move toward lead-free solder, driven by RoHS compliance and environmental health concerns. While lead-free solder presents its own technical challenges, it significantly reduces toxic exposure risks.

Additional material considerations include:

- Halogen-free laminates

- Low-VOC fluxes and cleaning agents

- Reduced use of hazardous surface finishes

These changes support safer working conditions while lowering environmental impact across the supply chain.

3. Energy Efficiency in Assembly Operations

PCB assembly relies on equipment such as reflow ovens, wave solder machines, and test systems — all of which consume substantial energy. USA-based facilities are increasingly investing in energy-efficient upgrades, including:

- Modern reflow ovens with optimized thermal profiles

- Smart power management systems

- Preventive maintenance to ensure equipment runs efficiently

According to the U.S. Department of Energy, energy-efficient manufacturing upgrades can reduce facility energy consumption by 10–30%, offering both environmental and financial benefits.

Green Circuit Board Manufacturing Practices in the USA

Process Control to Reduce Scrap and Rework

Every defective board represents wasted materials, energy, and labor. Sustainable PCB assembly prioritizes process consistency and quality control to minimize defects.

Common practices include:

- Automated optical inspection (AOI) to catch issues early

- In-process testing to reduce late-stage failures

- Statistical process control (SPC) for continuous improvement

Lower scrap rates not only reduce environmental impact but also improve delivery reliability for OEMs.

Responsible Chemical Management

Cleaning agents, flux residues, and surface treatments can introduce environmental risks if not handled properly. Eco-friendly electronics manufacturers focus on:

- Closed-loop chemical handling systems

- Proper waste disposal and recycling

- Reduced reliance on aggressive solvents

Facilities that invest in responsible chemical management demonstrate environmental stewardship while maintaining assembly performance.

Localized Supply Chains

Producing PCBs domestically helps reduce carbon emissions associated with long-distance shipping. Shorter supply chains also allow for:

- Faster engineering feedback loops

- Lower inventory waste

- Improved responsiveness to design changes

For environmentally focused OEMs, this localization supports sustainability goals while improving operational agility.

The Importance of Repair and Refurbishment in Sustainability

Extending Product Lifecycles

One of the most effective sustainability strategies is keeping electronics in service longer. Repair and refurbishment play a vital role in reducing electronic waste and conserving resources.

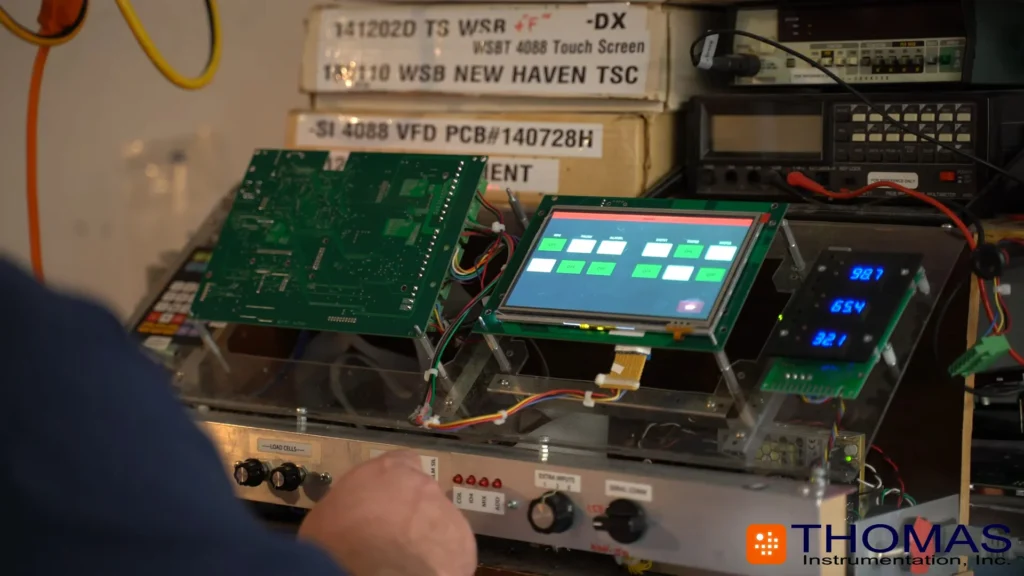

Rather than scrapping entire assemblies, manufacturers can:

- Diagnose and repair failed PCBs

- Replace specific components instead of full boards

- Refurbish legacy electronics for extended use

The International Telecommunication Union reports that extending the life of electronic products by just one year can significantly reduce lifecycle emissions, especially in industrial and commercial equipment.

Supporting Circular Manufacturing Models

Repair and refurbishment align with circular economy principles, where products are reused, restored, and redeployed instead of discarded. In PCB assembly, this may include:

- Component harvesting from obsolete boards

- Functional testing of refurbished assemblies

For OEMs producing long-life or mission-critical equipment, refurbishment is not only sustainable — it is often essential.

Reducing Cost and Environmental Impact Simultaneously

Sustainable practices are sometimes perceived as expensive, but repair-focused strategies often reduce costs. Refurbishment can:

- Lower material procurement needs

- Reduce lead times compared to new builds

- Decrease overall costs — refurbished PCBs are often less expensive than new builds for customers, helping save money while minimizing the throwaway culture of electronics

- Decrease disposal and compliance costs

From first-hand experience in electronics manufacturing environments, companies that prioritize repair capability often experience both sustainability gains and improved customer satisfaction, particularly in industries with long product lifespans.

Sustainability and Compliance Go Hand in Hand

Environmental sustainability is closely tied to regulatory compliance. USA-based PCB assembly facilities commonly adhere to:

- RoHS (Restriction of Hazardous Substances)

- REACH chemical safety standards

- Applicable U.S. state and federal environmental regulations

These frameworks provide structure for continuous improvement while helping OEMs meet customer and regulatory expectations.

What Environmentally Focused OEMs Should Look For

When selecting a PCB assembly partner, environmentally focused OEMs should evaluate:

- Commitment to sustainable PCB assembly practices

- Transparency around materials and waste handling

- Repair and refurbishment capabilities

- Energy-efficient manufacturing infrastructure

- Willingness to collaborate on eco-friendly design strategies

Thomas Instrumentation supports OEMs by aligning technical excellence with environmental responsibility, ensuring sustainability is built into both production and long-term product support.

FAQs About Sustainable PCB Assembly

1. What makes PCB assembly sustainable?

Sustainable PCB assembly focuses on reducing waste, using safer materials, improving energy efficiency, and extending product lifecycles through repair and refurbishment.

2. Is eco-friendly electronics manufacturing possible without sacrificing quality?

Yes. Modern USA-based facilities demonstrate that sustainability and high reliability can coexist through process control and smart design.

3. How does repair contribute to sustainability?

Repair reduces electronic waste, conserves raw materials, and lowers lifecycle emissions by keeping products in use longer. It also helps reduce the “throwaway” culture by extending the life of electronics instead of discarding and replacing them unnecessarily.

4. Are sustainable PCB assemblies more expensive?

Not necessarily. While some upfront investments may be required, reduced scrap, energy savings, and refurbishment options often offset costs.

5. Why choose USA-based PCB assembly for sustainability?

Domestic manufacturing offers stricter environmental oversight, reduced transportation emissions, and better collaboration on sustainable design initiatives.

Building a More Sustainable Electronics Future

Sustainable PCB assembly is no longer a future concept — it is an active transformation happening across USA-based electronics manufacturing facilities today. From waste-reduction strategies and energy-efficient processes to repair-driven lifecycle extension, sustainability is reshaping how PCBs are built and maintained.

For environmentally focused OEMs, working with partners like Thomas Instrumentation means choosing a path that balances innovation, responsibility, and long-term value. Sustainable practices are not just good for the planet — they strengthen supply chains, improve product longevity, and support smarter manufacturing decisions.