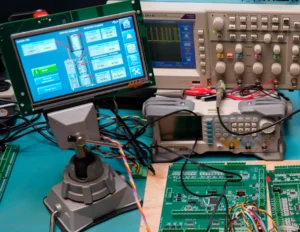

In laboratory and industrial environments, precision and reliability are non-negotiable. Whether it’s original, custom lab equipment, oscilloscope, multimeter, environmental sensor, or field diagnostic tool, the performance of every instrument depends on the integrity of the circuit board inside it. A single fault, fluctuation, or misreading can compromise data accuracy, safety, and reputation.

At Thomas Instrumentation, based in Cape May Court House, NJ, we specialize in high-precision, zero-failure PCB design and manufacturing for test and measurement electronics. We ensure boards are designed and built flawlessly, perform consistently, and last for years.

The Critical Role of Manufacturing Precision

In test and measurement applications, the margin for error is virtually zero. Instruments are trusted to calibrate, diagnose, and validate data in laboratories, manufacturing plants, and field environments. Even the smallest manufacturing inconsistency can cause signal distortion, measurement drift, or premature failure.

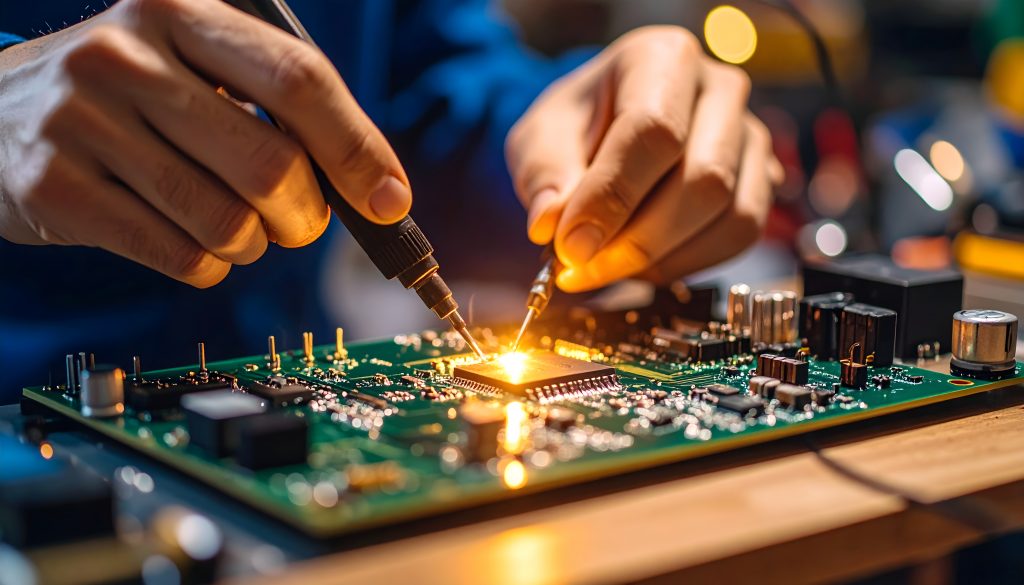

That’s why the quality of PCB design and manufacturing directly determines the accuracy of your equipment. At Thomas Instrumentation, every process step—from solder application to component placement—is executed with exacting precision under IPC-A-610 and ISO 9001:2015 standards.

Our process includes:

- Automated Optical Inspection (AOI) for 100% of boards to detect even the smallest solder or trace defects.

- Functional and in-circuit testing to confirm flawless performance before shipment.

- Full lot traceability and strict documentation for compliance and accountability.

This disciplined approach ensures 0% failure rates, consistent performance, and complete confidence in every PCB that leaves our facility.

Why USA-Based PCB Manufacturing Matters

Overseas production might appear to offer short-term cost savings, but in high-precision industries, the risks are substantial. A single defective board or an inconsistent batch can invalidate thousands of data points or halt a critical calibration process.

Choosing a USA-based PCB manufacturing partner eliminates many of these risks. At Thomas Instrumentation, we provide:

- Stable, Secure Supply Chains – All materials and components are sourced domestically, reducing risks of counterfeit parts and ensuring consistent quality.

- Fast Response Times – Local production allows rapid turnaround, immediate troubleshooting, and real-time communication with customers.

- Strict Quality Oversight – Beyond meeting ISO and IPC standards, we custom-calibrate our manufacturing lines to each product, ensuring consistent, high-precision builds that certifications alone cannot guarantee.

- Reliability and Longevity – Boards are built to perform continuously with minimal downtime or recalibration needs.

For OEMs building critical test and measurement devices, domestic manufacturing provides security, control, and predictable performance that offshore suppliers simply can’t match.

Applications Requiring High Reliability

Test and measurement equipment spans industries that demand absolute precision. Each device type places unique stress on its circuit boards—but all require consistent, high-quality manufacturing to achieve 0% failure rates.

Oscilloscopes and Multimeters

These instruments rely on flawless signal pathways and low-noise circuitry. Any variation in trace layout or solder integrity can cause measurement errors. Our U.S.-based manufacturing ensures every connection meets the tightest tolerances for repeatable, accurate readings.

Environmental Sensors

Air quality monitors, temperature controllers, and humidity sensors often operate continuously in variable conditions. We manufacture PCBs designed for reliability in fluctuating environments, ensuring consistent sensor accuracy over extended periods.

Portable and Handheld Testers

Devices like handheld spectrometers and field diagnostic units demand compact yet rugged PCB assemblies. Our manufacturing process is built for consistency, precision, and long-term reliability without compromising accuracy.

Industrial Diagnostic Tools

Equipment such as vibration analyzers and calibration instruments operates in challenging, electrically noisy settings. We manufacture boards that maintain stability and reliability under constant use—critical for industrial uptime and safety.

Data Loggers and Monitoring Devices

When devices collect long-term data, they must function continuously with perfect accuracy. Our boards are built to minimize energy loss, maintain calibration, and eliminate drift over long operating cycles.

In every application, manufacturing quality determines measurement integrity. That’s why we build each board as if it’s going into our own test equipment—because, in precision industries, there’s no room for error.

How Thomas Instrumentation Builds Reliability Into Every Product

Our commitment to product reliability begins well before a PCB reaches the assembly line. Instead of relying on generic templates or “one-size-fits-all” manufacturing rules, Thomas Instrumentation custom-calibrates the entire production line to each individual product. This includes tuning inspection parameters, soldering profiles, test protocols, and quality checkpoints specifically to that product’s electrical, mechanical, and performance needs. It’s this level of attention—beyond certifications—that sets our results apart.

Each PCB undergoes:

- Custom-defined visual and automated inspection criteria matched to the product’s design features, tolerances, and risk points.

- Calibrated soldering profiles configured specifically for the board’s materials, components, and layout to ensure consistent, high-quality joints.

- Functional testing using product-specific loads, inputs, and operating scenarios rather than generic testing templates.

- Post-assembly verification procedures tailored to the product’s required performance benchmarks, ensuring accuracy and stability.

And that level of customization continues through:

- Continuous improvement of build processes based on real product data

- Detailed documentation integrated into each product’s manufacturing profile

- Hands-on oversight from experienced technicians who understand the design intent

Through this product-focused approach—rather than relying solely on ISO paperwork—Thomas Instrumentation delivers the consistent reliability that our test and measurement customers depend on. This is why precision in laboratory equipment is a hallmark of our processes.

What OEMs Should Look for in a PCB Manufacturing Partner

When precision defines your product, manufacturing reliability must define your partner. Test and measurement OEMs should seek:

- ISO 9001:2015 and IPC-A-610 certified manufacturing.

- Proven records of zero defects or field failures.

- Secure U.S.-based sourcing and full traceability.

- Capability for medium-volume production (500–5000 units/month).

- Responsive, local communication for production or troubleshooting needs.

Thomas Instrumentation delivers all of these—supported by decades of experience serving laboratory, scientific, and industrial clients who depend on precision and uptime.

Frequently Asked Questions

Do you design test equipment electronics?

Yes. We design custom, original test and measurement equipment—such as laboratory analyzers, incubators, cell-culture devices, and specialized systems used in vaccine or biomedical production. We don’t develop generic off-the-shelf instruments like oscilloscopes; instead, we engineer one-of-a-kind devices created for a customer’s specific application.

How do you ensure reliability for precision instruments?

Through ISO-aligned processes, automated inspections, and rigorous functional testing—combined with the diligence and hands-on care of our manufacturing experts who monitor each product’s unique needs throughout production. It’s this expert oversight, not just the procedures, that drives our exceptionally low field-failure record.

Why choose U.S.-based manufacturing for precision PCBs?

Domestic suppliers provide stricter quality control, immediate communication, and secure supply chains—essential for sensitive, high-reliability products.

Can Thomas Instrumentation handle medium-volume runs?

Yes. We specialize in 500–5000 unit monthly production to support OEMs scaling efficiently without overcommitting to large inventories.

What makes your boards suitable for laboratory and industrial equipment?

Each PCB is designed and built for precision, consistency, and long service life, ensuring accurate data collection and stable performance over time.

Why OEMs Choose Thomas Instrumentation

Located in Cape May Court House, NJ, Thomas Instrumentation provides precision PCB design and manufacturing for test and measurement electronics requiring accuracy and reliability.

Our expertise includes:

- Explicitly highlight the diligence and care of your experts

- Emphasize design, precision component selection, and meeting or exceeding requirements

- Remove unrealistic guarantees

- Maintain a strong, professional tone

For OEMs in industries where accuracy equals reputation, Thomas Instrumentation delivers the precision manufacturing that keeps equipment performing flawlessly.

Partner with Thomas Instrumentation

Test and measurement electronics must meet the highest standards for precision, consistency, and durability. Working with an experienced U.S.-based PCB manufacturer ensures that every board you deliver performs with the same confidence as your brand.

If your company develops custom, original laboratory or industrial test equipment—such as blood analyzers, incubators, cell-culture systems, vaccine-production devices, or other specialized instruments designed for a specific scientific or industrial workflow—Thomas Instrumentation is the ideal manufacturing partner. Our expert-driven manufacturing process, precision component selection, and product-specific line calibration ensure that every circuit board meets or exceeds the performance, safety, and reliability requirements that your equipment—and your end users—depend on.