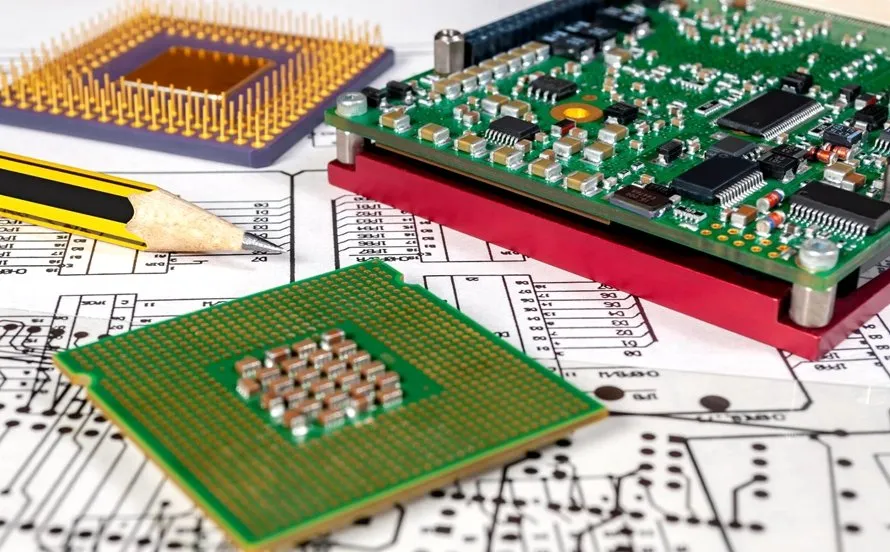

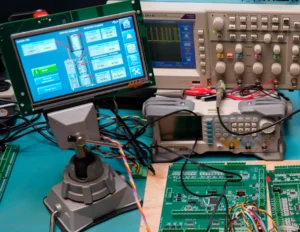

Design for Manufacturability (DFM) is the practice of engineering a PCB so it can be built reliably, repeatedly, and cost-effectively using standard manufacturing processes.

It ensures that a design not only performs electronically, but can also move smoothly through fabrication, assembly, and long-term production.

Why DFM Matters

A PCB that works perfectly in simulation can still fail during production if manufacturability isn’t considered early.

Good DFM reduces:

- Production delays

- Assembly defects

- Costly re-spins

- Supply chain bottlenecks

- Long-term quality issues

By designing with manufacturing constraints in mind from day one, you protect timelines, budgets, and product reliability.

Key Elements of DFM in PCB Engineering

- Clearances & spacing guidelines that match fabrication capabilities

- Optimized trace widths for current capacity and manufacturability

- Layer stackups that are consistent with industry standards

- Proper component footprints verified for solderability and assembly accuracy

- Thermal considerations for even heating during reflow

- Design rule checks (DRC) aligned with actual PCB manufacturer capabilities

Benefits for Product Teams

Implementing DFM early leads to:

- Faster time-to-market

- Lower cost per board

- Higher assembly yields

- Fewer ECOs late in the process

- Greater long-term reliability

DFM isn’t just an engineering step — it’s a competitive advantage.