Pharmaceutical and biotechnology laboratories are increasingly reliant on high-precision electronics to ensure quality, control, and regulatory compliance in every stage of their processes. From bioreactor controllers and centrifuge logic boards to cold-chain monitoring systems and vaccine development automation, printed circuit boards (PCBs) form the electronic backbone of this mission-critical infrastructure.

As laboratory equipment becomes more integrated with digital systems, pharmaceutical and biologics OEMs are making strategic decisions to insource more of their electronics production to trusted, U.S.-based PCB partners. For companies involved in vaccine formulation, cell culture automation, and sterile environment monitoring, these partnerships bring not only technical excellence but also security, agility, and process control compliance.

Growing Risks of Offshore PCB Sourcing in Biotech Lab Applications

Historically, many OEMs in laboratory equipment manufacturing relied on offshore partners for PCB production, drawn by the appeal of lower unit costs. However, the realities of post-pandemic supply chain disruptions and increasing regulatory scrutiny have shifted that landscape significantly. In 2024, the Reshoring Initiative reported a 27% year-over-year increase in reshored electronics production in the U.S., citing concerns about logistics stability, quality oversight, and data protection in overseas environments.

In pharmaceutical lab environments, the stakes of poor-quality PCBs are severe. Unreliable signal routing or inconsistencies in board impedance can lead to data logging failures, temperature drift in bioreactor controls, or even device shutdowns mid-process—all of which can invalidate months of R&D or critical GMP compliance cycles.

Security is also a concern. Devices used in pharmaceutical production often contain proprietary firmware and data interfaces. Manufacturing PCBs offshore creates a window of vulnerability for IP theft, firmware leakage, and reverse engineering. In contrast, working with a U.S.-based PCB partner allows OEMs to maintain full oversight of board production, firmware programming, and functional testing—all within ISO-compliant, traceable, and audit-ready environments.

ISO-Certified Production: A Mandate for FDA-Tracked Devices

Devices used in FDA-regulated laboratories must meet rigorous documentation and traceability standards. This applies not only to the final equipment but also to subcomponents like PCBs, which must align with ISO 9001 and IPC-A-610 Class 2 or 3 standards, depending on the application.

At Thomas Instrumentation, every PCB we manufacture for pharmaceutical laboratory clients undergoes:

- Automated Optical Inspection (AOI)

- X-ray verification for multi-layer assemblies

- Full materials and process traceability

- Lot-specific serialization

- 100% of Lot Functional System Testing

Our IPC-certified technicians document every stage of production, ensuring full compliance with Good Manufacturing Practice (GMP) guidelines. This traceability supports faster responses during FDA inspections or product recalls and reinforces long-term product safety in pharmaceutical environments.

According to the National Institute of Standards and Technology (NIST), domestic PCB manufacturers exhibit 40–55% lower defect rates than comparable offshore producers—a margin of quality that can mean the difference between a compliant production batch and a costly remediation process.

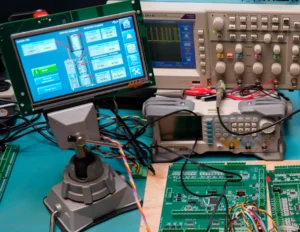

Collaborative Engineering for Complex Laboratory Control Systems

Laboratory and pharmaceutical devices often involve sophisticated embedded systems. Temperature feedback loops, pressure differentials, optical sensor arrays, and timing-critical motor controls all depend on robust PCB layout and design-for-manufacturing (DFM) alignment.

Unlike mass-market devices, laboratory equipment benefits greatly from early-stage engineering collaboration between the OEM and its PCB manufacturer. Thomas Instrumentation provides direct engineer-to-engineer communication during:

- Schematic reviews

- Layout adjustments for thermal management or EMI shielding

- Controlled impedance routing

- Bill of materials (BOM) optimization for traceable, RoHS-compliant components

This iterative design approach ensures smooth transitions from prototype to production, reduces board re-spins, and accelerates regulatory approvals. OEMs also gain access to our in-house testing protocols, including functional testing under simulated lab conditions.

While we do not specialize in high-frequency RF systems, our capabilities are tailored for laboratory instrumentation, signal processing, and microcontroller-based automation—the hallmarks of modern pharmaceutical equipment.

Controlled Volumes and Predictable Lead Times: Built for Laboratory OEMs

Pharmaceutical labs do not operate like consumer electronics brands. Their equipment rollouts are governed by validation cycles, pilot studies, and incremental facility upgrades. These realities demand a domestic PCB manufacturing partner capable of managing controlled production volumes with consistent build quality.

Thomas Instrumentation is uniquely positioned for mid-volume production cycles. We support:

- Quick-turn prototypes for benchtop testing

- Pilot-scale production runs for FDA validation

- Consistent mid-volume deliveries for phased deployment

- Flexibility in production scheduling to accommodate design or compliance adjustments

We maintain sub-1% defect rates across production runs and provide transparent scheduling to align with OEM development cycles. This minimizes inventory overstocking, reduces delays in deployment, and enables agile responses to evolving research needs.

Intellectual Property Security in Regulated Lab Environments

Pharmaceutical companies invest billions annually in research, and their laboratory equipment reflects highly customized workflows, proprietary control logic, and unique firmware integrations. Protecting this intellectual property requires full visibility and control over the production process.

Thomas Instrumentation manufactures all boards in-house at our New Jersey-based facility, ensuring no unauthorized access to Gerber files, firmware code, or confidential design elements. Unlike offshore vendors, we maintain:

- Non-disclosure agreements with all internal staff

- Data security protocols to protect the storage of all design assets

- Controlled access to firmware programming stations

- Secure version control and audit trails for all engineering files

By choosing a U.S.-based PCB partner, OEMs avoid the risks of unauthorized cloning or backdoor firmware injection—both of which have been cited in recent security audits involving offshore suppliers in adjacent industries.

Lower Total Cost of Ownership for Regulated Equipment OEMs

While unit costs for offshore PCB production may seem attractive, the total cost of ownership (TCO) tells a different story—especially in the high-stakes world of pharmaceutical manufacturing. Hidden costs tied to overseas production include:

- Extended lead times and inventory carrying costs

- Increased rework rates due to quality inconsistencies

- Delayed FDA submissions due to traceability gaps

- Expedited shipping during critical process failures

- Higher overhead from offshore vendor management and language barriers

According to the Reshoring Initiative, 46% of U.S. manufacturers reported cost savings after moving electronics production back to domestic partners. For pharmaceutical OEMs, these savings compound over multi-year contracts and reduce the likelihood of compliance-driven production halts.

Laboratory and pharmaceutical OEMs operate in a world where precision, compliance, and security are not optional—they’re mission-critical. U.S.-based PCB manufacturing isn’t just a smart choice for these sectors—it’s increasingly becoming a strategic necessity.

Thomas Instrumentation delivers ISO-certified PCB solutions tailored for laboratory automation, vaccine development, biologics manufacturing, and controlled-environment applications. With reliable mid-volume capabilities, real-time engineering support, and secure in-house production, we help pharmaceutical OEMs bring their next-generation devices to life—with confidence and control.

Ready to build lab-grade PCBs for your pharmaceutical equipment?

Please fill out the form on our Contact Page to connect with a PCB manufacturing specialist.