The electronics manufacturing landscape is undergoing a rapid transformation as U.S.-based appliance companies increasingly shift away from offshore printed circuit board (PCB) suppliers. Driven by logistics challenges, quality control demands, and compliance requirements, this trend is reshaping how mid-volume appliance manufacturers source critical components. For companies producing smart appliances, embedded systems, and connected consumer products, domestic PCB suppliers offer unmatched advantages in responsiveness, compliance, innovation, and reliability.

This article outlines the factors accelerating this shift and highlights why appliance OEMs are turning to trusted partners like Thomas Instrumentation to secure a more agile and resilient electronics supply chain.

Strengthened Supply Chain Resilience with Proven Performance

In the wake of the COVID-19 pandemic, ongoing trade disputes, and global freight disruptions, many North American electronics manufacturers experienced delays and bottlenecks that exposed the vulnerabilities of overseas sourcing. According to a 2023 IPC report, 84% of North American electronics manufacturers faced supply chain challenges in the previous two years.

However, Thomas Instrumentation was not among them.

Thanks to proactive forecasting, flexible sourcing strategies, and an established domestic supplier network, Thomas Instrumentation avoided production delays entirely, setting it apart from the majority of the industry. Their ability to adapt to customer design changes and maintain on-time delivery has positioned them as a resilient partner for appliance manufacturers.

Key Advantages of Domestic PCB Sourcing for Supply Chain Stability:

Shorter Lead Times: U.S. manufacturers like Thomas Instrumentation typically deliver custom PCBs in 2–4 weeks, compared to 8–12 weeks for Asian vendors.

Reduced Freight Costs: Eliminating ocean freight, tariffs, and customs duties translates into immediate cost savings and fewer logistics headaches.

More Predictable Delivery Schedules: Local production allows better inventory management and mitigates the risks of delayed shipments and last-minute disruptions.

Refurbishment and Repairs: With a domestic partner, repair and refurbishment programs become feasible — saving appliance manufacturers money while extending the lifecycle of legacy products.

With a domestic supplier, you can save on costs by having a refurbishment program that brings new life into older products.

Improved Quality Control and Compliance

Appliance manufacturers demand high reliability, particularly when producing embedded systems with sensors, AI modules, and power management. U.S.-based PCB suppliers deliver consistent quality assurance that offshore vendors often cannot match.

How Thomas Instrumentation Supports Superior Quality:

Strict Standards: Thomas Instrumentation adheres to IPC-A-610, ISO 9001, and other industry certifications to ensure top-tier electronic assembly quality.

Real-Time Oversight: Being stateside enables closer customer collaboration, live factory audits, and transparent visibility into production processes.

Rapid Problem Resolution: In the rare event that an issue arises, Thomas Instrumentation resolves it swiftly, avoiding the delays associated with overseas troubleshooting.

Defect Rates Below 1%: Thomas Instrumentation maintains a manufacturing defect rate of less than 1%. Every defect is analyzed at the root — whether the cause is a component anomaly or a unique field-use scenario.

“We take your issues seriously and do everything in our power to remedy them — defects hurt the bottom line and can cause brand reputational damage.” — Cassandra Gluyas, Thomas Instrumentation

According to the National Institute of Standards and Technology (NIST), U.S. electronics manufacturers report defect rates 40–60% lower than comparable offshore facilities. This distinction makes a measurable impact on long-term product performance and warranty costs.

Compliance with Domestic Regulations and Customer Expectations

Today’s consumers and regulatory agencies are more concerned than ever with the ethical, environmental, and cybersecurity dimensions of electronics production. U.S.-based PCB manufacturing better aligns with these priorities.

Regulatory Adherence: Domestic suppliers comply with the National Defense Authorization Act (NDAA), ITAR, and RoHS standards — essential for appliance makers with federal or international compliance exposure.

Data & IP Protection: Proximity to U.S. soil provides greater control over sensitive embedded systems, firmware, and software — reducing the risk of IP theft or code tampering.

Sustainable Manufacturing: Many U.S. PCB fabricators, including Thomas Instrumentation, embrace cleaner processes that reduce hazardous waste and carbon output.

A 2024 Deloitte report found that 72% of American buyers prefer appliances built with domestically sourced components, citing trustworthiness and environmental responsibility as major decision drivers. Working with U.S. partners like Thomas Instrumentation reinforces these consumer values.

Enabling Innovation in Smart Appliance Electronics

As smart appliances incorporate more advanced features — from IoT connectivity and AI-based automation to energy optimization — the need for tight integration between design and manufacturing becomes essential.

Thomas Instrumentation plays a critical role in helping OEMs meet this demand through rapid iteration and technical collaboration.

Innovation Advantages from Thomas Instrumentation:

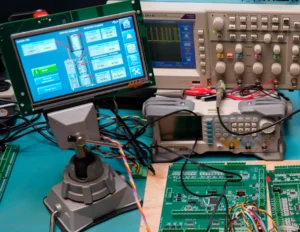

Collaborative Design Support: Thomas offers DFM (Design for Manufacturability) consultations to help optimize PCB layouts for cost, space, and power.

Rapid Prototyping: With in-house capabilities, Thomas can turn around working prototypes faster — reducing time to market.

Advanced Capabilities: They offer rigid-flex PCBs, embedded electronics, and multi-layer boards engineered for compact form factors used in modern appliance designs.

Access to Cutting-Edge Technology: Unlike many foreign competitors, Thomas Instrumentation is not subject to export-control restrictions that limit access to the most advanced U.S. technologies.

Foreign design houses often do not have access to the latest technologies because they are export-controlled. U.S. design partners can help you access the most state-of-the-art capabilities.

This technical edge enables appliance manufacturers to launch next-generation devices with confidence in both performance and compliance.

Economic Competitiveness Is Shifting

Although offshore PCB manufacturing once delivered labor cost advantages, rising global wages, trade instability, and shipping costs are closing that gap. According to a 2023 Reshoring Initiative report, 48% of U.S. manufacturers now cite total cost of ownership (TCO) benefits as their primary reason for bringing suppliers back onshore.

Domestic production reduces:

- Inventory Carrying Costs

- Rework Expenses

- Freight Overhead

- Administrative and Quality Escalation Costs

When factoring in these holistic cost considerations, working with a U.S.-based supplier like Thomas Instrumentation is not only strategically sound but often more cost-effective than overseas options.

Supporting National Security and Economic Resilience

Beyond cost and performance benefits, reshoring also supports long-term national priorities. The U.S. government has recognized domestic electronics production as vital to both economic and national security.

In 2022, the CHIPS and Science Act earmarked $52 billion for semiconductor and electronics manufacturing growth in the U.S.

The Department of Commerce continues to fund and promote domestic PCB supply chain efforts to reduce dependence on overseas production.

By partnering with domestic experts like Thomas Instrumentation, appliance manufacturers help build a more resilient national industrial base while shielding themselves from global disruptions.

Why Appliance OEMs Choose Thomas Instrumentation

Thomas Instrumentation stands at the forefront of the reshoring movement, delivering superior PCB assemblies, design collaboration, and responsive service that today’s appliance OEMs demand. With demonstrated resilience during global disruptions, a defect rate under 1%, and deep engineering expertise, Thomas offers unmatched performance and peace of mind.

When manufacturers need to meet high standards for speed, compliance, durability, and customer satisfaction — Thomas Instrumentation delivers.

Take the Next Step Toward High-Performance Appliance PCBs

Need a PCB partner who delivers speed, quality, and reliability without the global disruption risks? Connect with Thomas Instrumentation today or call 609-624-7777 to get started with a trusted domestic supplier who understands the needs of modern appliance manufacturers.