Inspection

In order to provide excellent service, Thomas Instrumentation has invested in quality inspection equipment for its technical department. The tools we have available are an X-Ray Inspection machine, an Automated Optical Inspection (AOI) machine, two Tagarno Digital Inspection stations, a Mantis Vision station, a Lynx Vision station, and a Pace rework station. These tools allow our careful technicians to provide top notch quality control of our customer’s products. The following is a more detailed look into our equipment:

X-Ray Inspection

Our Creative Electron TruView Fusion X-Ray inspection system is powerful and versatile. It can use x-ray sources from 80kV to 150kV, achieve magnifications up to 2,000X, and has fully automated defect detection capabilities. We use this system to inspect components with solder joints that aren’t easily seen, such as BGAs, to ensure our solder paste and oven profiles are correct. This gives customers with small boards and/or more difficult components a high confidence in the quality of their final products.

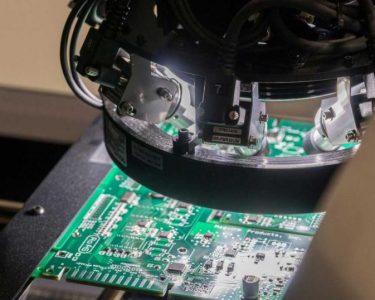

Automated Optical Inspection (AOI)

Our MEK PowerSpector AOI machine is used to refine our production process by identifying any errors or emerging process trends. It can inspect parts for presence, absence, position, polarity, type, offset, text, color, etc. The AOI system can also review component solder fillets for excessive solder, insufficient solder, no solder, shorts, lifted leads, etc. These inspection points help us rapidly verify that all the correct parts were placed accurately. While the machine can be time-consuming to program, there is a great deal of value for larger production volumes. The value added is in reducing the time required for visual, quality control assessments of each board. Rather than inspecting 100% of the product, we only need to review boards that fail the AOI inspection process.

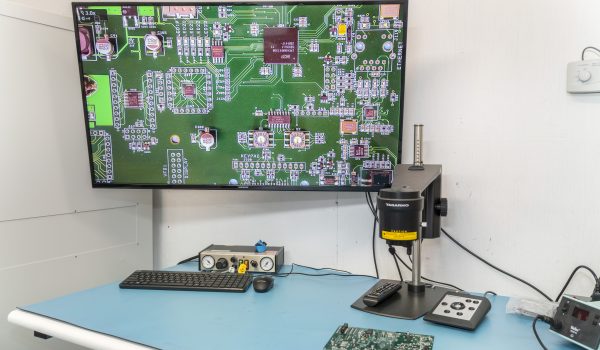

Tagarno FHD Trend Digital Microscope

Thomas Instrumentation has 2 Tagarno FHD Trend microscope stations attached to large monitors at our facility. These two systems have magnification levels from 1.3x – 330x, a 30x optical zoom, 60fps ultra-high frame rates, full HD/1080p image quality, and the ability to capture images to a PC. We primarily use these microscopes to visually inspect and perform modifications or repairs to a product. However, we’ve also found it useful for documentation of new products and/or issues that we need to discuss with others. It is a very versatile inspection tool.

Mantis & Lynx Vision Systems

Our technical department has these 2 other manual vision inspection stations. They are both stereo vision systems manufactured by Vision Engineering, have long working distances, and variable magnification. That said, the Lynx system has the highest level of magnification which is 120x. These two systems allow our technicians to easily inspect and perform modifications or repairs to any product.