Diagnostics

Basic Trouble-Shooting

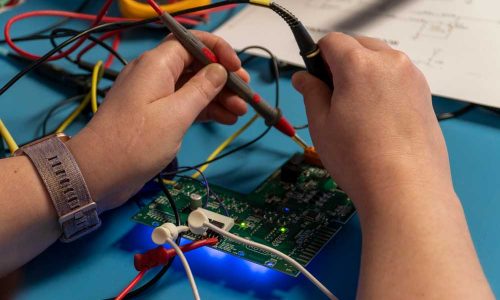

Our technicians were originally trained by either a Technical College for Electronics or courses from the Air Force. Thus, they all had a strong background in Electronics before coming to work at Thomas Instrumentation over 20 years ago. Our technicians can easily read schematics and PCB layouts to trace out circuitry issues. They also have access to a plethora of diagnostic equipment including but not limited to multimeters, oscilloscopes, function generators, frequency counters/timers, logic analyzers, spectrum analyzers, precision voltage sources, power supplies, thermocouple calibrators, ESD simulators, burst generators, and more.

We’ve seen a lot here in our 40+ years and we know that even good designs sometimes run into an environment that causes problems. When this happens, customers reach out to our technicians who use the tools available to find the root cause of the problem. Our technicians then collaborate with our electrical engineers to devise a solution which may be a PCB mod, a PCB revision, or sometimes just a software update. With the combination of technical experience and equipment available at Thomas Instrumentation, we can diagnose almost any electronic issue.

Specialized EMI/EMC Testing

Two of the main problems that plague electronics is ESD electrical noise and poor-quality power sources. Due to this, we decided to invest in an ESD Simulator and a Burst Generator to test our designs for noise immunity. This means all our customers can have these tests run before submitting products for MET Lab testing and certifications.

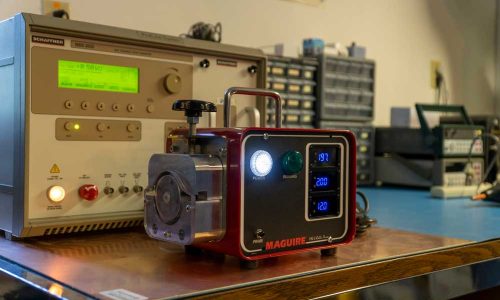

ESD Simulator

This device generates both airgap and contact electrostatic discharges between 2kV and 21kV. This device will thoroughly test a products ESD immunity, so we’ll quickly find out if the design is solid or if it needs any changes. This increases customers’ confidence in their products reliability.

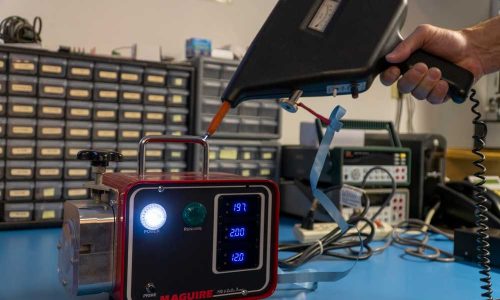

Burst Generator

This device generates different forms of electromagnetic interference, such as Electrical Fast Transient pulses, on a device’s power line. Essentially, it simulates inconsistent or faulty power sources. When customers have this test performed, they will quickly discover if their design will survive and recover from these common power problems. If it doesn’t then we help them tweak their product until it does pass. This again gives customers confidence in their design going into any certifications or noisy environments.